How tire pressure systems lower maintenance costs

Integrated vehicle tire pressure monitoring systems (IVTM) can create significant reductions in truck and trailer maintenance costs while also providing safer driving and better fuel mileage.

Properly maintained tire pressure can sharply reduce blowouts, for example, which not only improves vehicle stability and mitigates chances of accidents, but also saves on tire replacement and road calls.

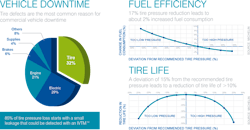

Moreover, research by Michelin shows that 15 percent overinflation or underinflation can reduce a tire’s lifespan by 10 percent. Because tire defects are the most common reasons for commercial vehicle downtime, clearly, productivity is enhanced if tire pressure remains at specified levels.

Advantages of Technology

There are numerous other advantages of the technology. It’s calculated that constant tire pressure can boost fuel economy by up to 2 percent, a key factor as federal mileage targets loom in the near future.

The U.S. Environmental Protection Agency (EPA) reports that underinflation by as little as 10 psi can trim fuel usage between 0.5 percent and 1 percent. Greater rolling resistance caused by underinflated tires also can increase unwanted carbon emissions.

Importantly, tire life can be extended up to 20 percent by adhering to recommended pressure levels, and vehicles with underinflated tires require longer braking distances, which is also a safety issue.

A National Highway Traffic Safety Administration (NHTSA) report indicates that defective tires are the leading cause of crashes involving commercial vehicles. This underscores the pivotal role of constant tire pressure monitoring as instrumental to accident avoidance.

Automatic tire inflation systems are among technologies named in proposed NHTSA regulations.

There’s also this to consider when looking at the issue from a total cost standpoint: Tire pressure and inflation conditions are the second leading cause of roadside inspection citations, based on a study of tire pressure and inflation done by the Technology & Maintenance Council (TMC). Reliable monitoring likely can shrink the number of such citations.

Several tire pressure systems include sensors at each wheel of the tractor and trailer and an Electronic Control Unit (ECU) that relays information to an in-cab instrument panel console to constantly alert drivers of changes in pressure. Slow leaks also are detected.

Tire pressure information available to the driver also can be conveyed via a web portal to the fleet manager or dispatcher using text or e-mail, enabling prompt action when necessary.

Developments

Numerous technologies to expand tire pressure oversight capabilities are now on the market or coming soon. One system, for example, automatically maintains proper inflation by supplying air in tractor tires. A future option will regulate up to eight wheels while measuring each tire’s internal temperature.

Another system obtains temperature and pressure readings directly from inside the tires, communicating this information wirelessly to an onboard receiver, transferring real-time data to a dashboard display.

In addition, a different system provider recently celebrated the delivery of its millionth tire pressure monitoring solution. This particular system has available wheel-end sensing technology that detects abnormally high temperatures caused by wheel bearing, seal or other internal wheel-end problems, indicating that inspection and repairs should be made to lower the risk of serious, costly failure.

To help fleet managers figure their return on investment (ROI) savings, many suppliers have developed calculators where you simply input your specific vehicle data or load a standard profile. The calculator determines the payback period and monthly savings, and also helps gauge the impact of underinflated tires.

A Look Ahead

Tire pressure monitoring systems have been available in passenger cars and light trucks for some time, but systems for commercial vehicles are subject to more rigorous and varying conditions. Therefore, they require a more robust approach. Besides saving tires that can live again as retreads, today’s commercial vehicle systems also can be retrofitted to existing vehicles within a normal maintenance cycle and negligible downtime.

What about the future? Current technologies such as stability control and collision mitigation are both platforms for autonomous driving that has Silicon Valley and Detroit buzzing.

It’s not inconsistent to assume that tire safety, made possible by integrating tire pressure monitoring systems, is an integral part of our autonomous driving future. As one astute engineering expert, Dave Cole, chairman emeritus of the Center for Automotive Research (CAR), puts it: “What happens if you’re in a stream of driverless vehicles speeding 80 mph and someone has a blowout?”

Jon Morrison, a 30-year veteran of the global transportation industry, is president for WABCO’s Americas Business Unit. WABCO (www.wabco-auto.com) is a leading innovator and global supplier of technologies that improve the safety and efficiency of commercial vehicles. In North America, it is recognized as an industry leader in advanced vehicle control and braking systems, including collision mitigation systems.