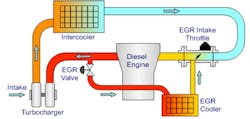

Introduced in October 2002, the exhaust gas recirculation (EGR) system was added to heavy duty engines in order to meet the U.S. Environmental Protection Agency’s (EPA) emissions standards at that time. The function of the EGR system is to reduce NOx emissions.

“EGR systems take a portion of exhaust gases from the exhaust manifold and recirculate them through the intake track to reduce oxygen content in the cylinders,” says Kevin Smith, field analyst for Dorman Products, a supplier of OE dealer replacement parts. “The main goal of this system is to reduce NOx emissions made during combustion. By lowering the oxygen content in the cylinders, the temperature of combustion is lowered, therefore reducing the NOx emissions that are being created by the engine. A byproduct of this system is increased soot production. This is where the aftertreatment system steps in to collect and periodically burn the soot that is collected in the diesel particulate filter (DPF) into ash.”

Technological advancements

Since the EGR system’s introduction, the main components of this system have stayed the same – cooler, valve, actuator, etc. However, improvements have been made.

“Coolant is used to reduce the temperature of the exhaust gas, and an important factor in cooling the engine is pressure through the system,” says Michael Young, Detroit engine marketing manager for Daimler Trucks North America (DTNA), a manufacturer of commercial vehicles. “In 2021, the EGR system in Detroit’s DD15 Gen 5 (engine) will allow for reduced pressure drops through the system, making the whole cooling system perform better. With the DD15 Gen 5, we will also update how coolant flows and will be able to reduce the amount of parts in the system.”

In addition to the reduced pressure drops, Young explains that the EGR valve has been updated. The valve has been incorporated into the exhaust manifold center, which will improve EGR flow management, as well as control over over-the-road emissions and performance.

Over the years, as the EPA has lowered the acceptable levels of emissions, EGR has been reconfigured to meet those goals, Smith says. And, with the new lower level requirements, other technology has also been introduced. In 2007, DPFs came onto the scene, and then in 2010 when emissions standards were lowered again, the selective catalytic reduction (SCR) system was introduced.

“SCR is a chemical reaction process where DEF (diesel exhaust fluid) is injected into the SCR unit and when operating properly, the ammonia in DEF reacts with the NOx emissions and breaks them down into nitrogen and water molecules,” Dorman’s Smith explains.

Today, both SCR and EGR systems are incorporated into heavy duty diesel engines. Each system plays an important role in reducing NOx emissions; however, each system also has its drawbacks.

According to Kristopher Ptasznik, product manager, heavy duty on-highway for Cummins, a corporation that designs, manufactures, and distributes engines, filtration, and power generation products, though EGR systems shrink NOx emissions, they can cause an increase in particulate matter (PM). As for SCR systems, though they also break down NOx emissions, they create an increase in diesel exhaust fluid (DEF) consumption. Regardless of their faults, the SCR and EGR systems working together are the best solution to lowered emissions levels.

Additionally, when combined with a DPF, “EGR and SCR [systems have] been proven to reduce NOx emissions by at least 80 percent in a well-maintained truck, and in some systems, even more than that,” Smith says.

Challenges with EGR systems

It is important to know the challenges that come along with maintaining an EGR system.

“There are a few major failures that can occur,” Doorman’s Smith explains. “EGR coolers have two main failure modes: plugging with soot, which restricts the flow of the gasses through the system; and fractures inside the cooler from thermal cycling and constant pressure being applied to the system.”

An internal crack in an EGR cooler can cause significant damage to any components or systems downstream, Smith notes. Additionally, failures with EGR valves are typically caused by soot and carbon buildup.

Aside from these major component failures, many small failures can also impede the function of the system, Smith continues. Some of the small failures include air leaks from torn gaskets, stretched clamps, ripped couplers, which can cause inaccurate readings to the pressure and temperature sensors, electrical faults of the sensors and EGR valve, and an increase in soot. This increase can not only damage the EGR system, but the turbocharger as well.

Another common challenge with EGR systems is coolant leaks, Daimler’s Young notes. Young recommends pre-trip visual inspections to help mitigate larger problems.

When these problems arise, they affect not only the EGR system, but the engine and aftertreatment system as well. In some instances, components in the EGR system may need to be replaced in order to fix the problem.

EGR valves and coolers can be replaced with either brand new components or remanufactured components, Smith explains. Brand new parts typically have the best value as they have not been used before, where with a remanufactured part it is impossible to know what the part went through with prior use and how effective it will be moving forward.

“Fortunately, the aftermarket has the opportunity to step in and analyze the main failure points on these parts and can redesign them to make them more efficient than the original manufacturer and withstand the operating environments for longer service life,” Smith says. “At Dorman, we have taken all the major failure modes of EGR valves and coolers and redesigned them to have a longer service life than the original components that came on your engine.”

Dorman has taken the usual bar and fin style of EGR coolers which tended to trap soot and upgraded some of their coolers to a spiral tube design, Smith says. This helps prevent clogging as the soot can move more efficiently through the cooler. The company has also upgraded bushings on the EGR valve as well as added a more robust electric motor to withstand the tension caused by soot and carbon buildup within the valve, granting the component a longer service life.

Servicing EGR systems for peak performance

For fleets to keep their EGR systems running properly, technicians must have the necessary tools for diagnosing, maintaining, and repairing EGR systems.

Dorman’s Smith recommends technicians have a diagnostic scan tool and borescope as well as an EGR cooler pressure tester if they are working on these systems frequently.

“Having the ability to monitor the operation of the EGR system while it is in use as well as the functionality to run tests on its components is extremely important in diagnosing what has failed. This will narrow down your troubleshooting procedures to a target area of the system where the fault is occurring and, in some cases, point you directly to the component that is faulty,” Smith says of using a diagnostic computer. “Aside from a diagnostic [scan tool], my personal go-to tool [is] a borescope, which allows me to take a look inside the components without disassembling the entire system to inspect.”

It should be noted, however, that many EGR components are not serviceable and are not recommended to be disassembled, Daimler’s Young says.

This is where training comes in. As with any heavy duty vehicle system, training is crucial to properly diagnosing and maintaining the EGR system.

“Understanding how they operate and knowing what sensor readings should be when the system is operating properly is key to spotting where your fault may be,” Smith says. “There are many companies and schools that offer training on EGR systems.”

Another aspect of maintaining EGR systems is cleaning them. Like many engine components, the EGR system can become clogged with soot and PM.

Not all components of the EGR system are able to be cleaned and reused; some fleets will just have to replace components.

“When it comes to the EGR cooler [itself], there are several companies nationwide that can successfully wash out the EGR cooler with a high-pressure water-based cleaning solution,” Smith says. “The only drawback is that you still have a used EGR cooler that may fail soon after reinstallation. This is similar to using a remanufactured EGR cooler.”

In addition to proper maintenance and cleaning of the EGR system, fuel type also plays a role in reaching peak performance, Young notes. Ultra-low sulfur diesel fuel is vital to keeping the engine, aftertreatment system, and EGR system functional and long lasting.

As EGR technology continues to progress, the importance of keeping up with proper maintenance practices is more important than ever. A technician cannot do their job without thorough training and the correct tools and equipment.

About the Author

Emily Markham

Assistant Editor | Vehicle Repair Group

Emily Markham is an assistant editor for the Vehicle Repair Group.

With an education based in writing and editing, Markham uses her knowledge to assist with the creation of content for Endeavor Business Media Vehicle Repair Group’s publications—Fleet Maintenance, Professional Tool & Equipment News (PTEN), and Professional Distributor—as well as their website, VehicleServicePros.com.