Aero device ROI: Private vs. for-hire

Fuel economy gains for aerodynamic devices and their effect on the bottom line varies depending on fleet type and the maintenance culture within the organization. As fuel prices continue to rise, some marginal devices may now show a reasonable return on investment. However, the maintenance and operational impact of some devices need to be evaluated and become part of your business case to fully understand the impact.

Fleet type and operation

The two major fleet types, private and for-hire, view maintenance operations differently and that means presenting the business case for maintenance activities must be adjusted. Private fleets, whose maintenance operations are seen as a cost center, look at ways to reduce cost because the savings decrease the cost of their product—or it may go directly to their bottom line.

On the other hand, private fleets often use their vehicles as part of brand enhancement. A well-maintained, good-looking fleet is an intangible positive asset. For-hire fleets seem to have a better understanding of the maintenance investment, as their assets are nearly all rolling stock and the ratio of revenue-to-assets is much higher than in a private fleet’s. In either case, justifying aerodynamic maintenance starts with understanding the value of the aerodynamic devices.

Type of haul also affects how the maintenance business case will look. Regional hauling implies some constraint on geographic operation to allow the driver to return home on some predictable basis. NACFE defines the scope of regional haul as operations in which the truck stays within a 300-mile radius of a home base. This may include trucks that return to a home base every day or ones on a route for multiple days but that stay within that 300-mile radius. Long haul is usually defined as routes that require the driver to be on the road more than a couple nights and most of the driving is done at highway speeds, or above 50 mph.

Aerodynamic drag is the number one factor affecting fuel economy at highway speeds over 50 mph. The adoption of aerodynamic devices on both the tractor and trailer, with cab extenders, trailer skirts, wheel covers, trailer tail extenders, and more is seen as a necessity for competitiveness. The correct combination of these devices can increase fuel mileage by around 15% or more. But for these aerodynamic devices to work, they must be properly installed and maintained. Interest in these devices always rises as fuel prices increase, so now is a good time to have a little refresher on building a business case for maintenance.

See also: MVTS tests aerodynamic fuel-saving tech for trailers

Long-haul example

For a long-haul operation that travels approximately 150,000 miles a year, averages 7.27 miles per gallon (according to NACFE’s 2019 Annual Fleet Fuel Study) using diesel fuel that is averaging $4.107/gallon, the fuel bill would be approximately $85,000 a year. Using the current national average of $5.62/gallon, that equates to $115,543.

Cab side extenders offer an estimated 2% fuel economy improvement. Assuming the cab side extenders would provide a 2% improvement in fuel economy, and factoring in the lower $4.107/gallon, the fleet would save about $1,700 per year in fuel cost and would have a payback for the device in one year. They would save $2,310 at the current diesel rate. After the payback period, the device would be adding to the fleet’s profitability or bottom line. See the formulas below for a visual representation of this example.

The key to aerodynamics is attaching air to the cab/trailer and keeping it attached until it’s released by the trailer, but what happens if the aero devices are not maintained correctly? Air flow is disrupted and causes an increase in drag, additional noise because of vibration, or even an unsafe operating condition that may place a vehicle out-of-service. And although the aerodynamic devices seem robust, road conditions and even air pressure exert enormous forces on the simple looking panels and fastening locations. It is not uncommon to see numerous design revisions during the evolution of even the simplest looking components.

Let’s assume half the effectiveness (1%) of the cab side extenders because a driver jackknifed the trailer into them, and they no longer are properly aligned or they are cracked. The payoff will go from the expected 12 months to 24 months, which is a significant change. See the formulas below for a visual representation of this example.

Private carrier example

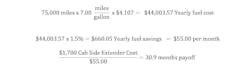

Private carriers are usually regional haul operations with lower road speeds and fewer miles. They usually take longer to get to a breakeven point, but there is still value in aerodynamic devices and maintaining them. Assume the same cab side extenders at 75,000 miles per year, and only a 1.5% improvement in fuel economy because of reduced speeds and fewer miles traveled. As shown below, the payback would be about 31 months.

A four-year trade cycle would have a breakeven of about 31 months and the savings would continue for 17 months after the side extender’s premium is paid. But if not maintained and the same half effectiveness is considered in a short-haul application, the cab side extender costs are not even recovered and are actually a penalty at the same four-year, 48-months trade cycle. See the formulas below for a visual representation of this example.

Maintenance culture

In a private company, the maintenance culture is driven by corporate culture. Private companies generate revenue by the products they manufacturer and because of that, each department becomes a cost center and is managed by its income contribution. Regrettably, maintenance departments in private companies don’t generate an income and cost avoidance is often the rule rather than the exception. Some support can be gained because private companies do place high emphasis on company image and a floppy cab extender doesn’t present a good image.

It’s nearly opposite in a for-hire company. These companies generate revenue by having their rolling assets move efficiently. So, improving efficiencies, either by spec’ing a component with a short payback or keeping the component that was spec’d to run efficiently, improves the revenue generated. Although company image may not be emphasized as much, it is still discussed at the highest levels in the company. With company image and efficiency, the support for quicker repairs is a no brainer.

The maintenance department’s culture within the company is a major influencer on aerodynamic device repair decisions and how quickly a repair should be scheduled or even if it should be scheduled before the asset is prepared for trade.

In either type of operation or culture, understanding, and being able to present, the business case is an important part of managing the maintenance department.

About the Author

Frank Bio

Frank A. Bio, FABio Transportation Consultation founder and president, has been part of North American Council for Freight Efficiency since 2019, contributing to Confidence Report updates and various other assignments including autonomous and electric vehicles. Prior to retiring from Volvo Trucks as director of sales development – specialty vehicles and alternative fuels, Bio led Volvo’s sales force education and portfolio for alternative fuel and specialty vehicle. He also advised motor carriers considering alternative fuel vehicles and vocational trucks. Bio started his career in 1972 in the heavy-duty commercial vehicle industry, serving in a variety of positions including engineering, service, marketing, and sales.