Shell launches E-Fluids for electrified commercial vehicles

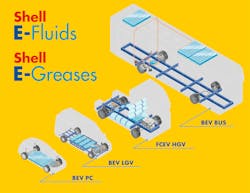

Shell extended its globally available specialized fluids portfolio – Shell E-Fluids – to support battery electric (BEV) as well as fuel cell electric (FCEV) powertrains for commercial light, medium, and heavy duty vehicles. Shell works with truck and bus manufacturers to co-engineer bespoke fluids that meet the specific needs of their different electric drivetrains for their commercial vehicle models.

This extension to the portfolio builds on the successful launch of the Shell E-Fluids range for passenger vehicles in May 2019. With this expansion to the portfolio, manufacturers of all electric vehicles from passenger cars to vans to larger trucks and buses can now benefit from the extensive range of specialized Shell E-Fluids and E-Greases.

“Once added to the sealed environments of BEV or FCEV commercial vehicles, the fluids need to perform at optimum levels over the vehicle’s lifetime; this is why first fill is so important for electric vehicles,” said Carlos Maurer, executive vice president, global commercial, Shell. “We have used Shell gas to liquid (GTL) base oil technology for the Shell E-fluids portfolio because its low viscosity properties allow for higher efficiency in the vehicle’s powertrain. Our lubricants research laboratories have focused on delivering cutting-edge fluid solutions to meet the specific electric drivetrain challenges of temperature control, oxidation, copper erosion, and thermal conductivity.”

The commercial road transport sector, which delivers goods to shops and consumers’ homes as well as providing public transport, emits 8 percent1 of global energy-related CO2. The lead to decarbonize road freight is being driven by policy action in markets such as the EU, China, South Korea, and Japan as well as voluntary action by corporations. Both BEV and FCEV solutions will have a role to play because the pathways and timelines for road freight decarbonization will vary by geography, sector, and duty sector. Shell E-Fluids is one of the ways that Shell is partnering with the commercial vehicle sector to help deliver decarbonization pathways.

The Shell E-Fluids range for commercial vehicles consists of e-transmission fluids, e-greases, and battery thermal fluids. To date, commercial vehicle manufacturers have had to predominantly rely on a range of fluids, which have been developed for internal combustion engines vehicles and do not deliver the necessary performance and efficiency for electric powered vehicles.

Performance benefits of Shell E-Fluids for commercial vehicles

The Shell E-fluids deliver:

- Oxidation stability which results in longer lifetime of the lubricant to avoid as much as possible any maintenance downtime or oil changes needed during the lifetime of the vehicle

- Even at high temperatures, standard oxidation tests show that the Shell E-Fluid Technology oxidizes 50 percent less compared to a competitor E-Fluid solution.2

- Up to 8-times lower electrical conductivity when cooling the electric motor under typical operating conditions temperatures, compared to a conventional transmission fluid designed for heavy duty ICE commercial vehicles.3

- More than 3-times less copper erosion compared to a competitor’s specialized E-Mobility driveline fluid, due to the reduction of sulfur content in combination with its optimized additive system.4

- Up to 9 percent higher thermal conductivity compared to a competitor’s specialized E-Mobility driveline fluid, enabling higher cooling capabilities for end windings of electric motors and gearbox lubrication.5

- 8 percent includes trucks and buses: Source: IEA Tracking Transport 2019, IEA Energy Technology Perspectives 2017, IEA Future of Trucks Based on DKA Oxidation Test 170 degrees C/192hr, comparing kinematic viscosity increase at 100 degrees C. Comparing electrical conductivity data, measured to mod. DIN 53483 at 500V. Shell E-Fluid Technology versus conventional Heavy Duty ATF Shell E-Fluid E6 i Plus 75W versus competitor e-fluid in mod. ASTM D130 Cu-Strip Test at 168hr/150 degrees C; Measurement of Copper in oil acc. DIN 51399-2. Comparing Thermal Conductivity data at 120 degrees C / 140 degrees C between Shell E-Fluid Technology and a Competitor E-Fluid solution acc. to ASTM D7896-19