Inside look at Navistar’s new truck assembly plant

SAN ANTONIO—Navistar’s newest truck assembly plant here in Texas will serve as the “operational backbone,” bringing high-tech industry concepts to the OEM’s existing plants in North America.

According to the OEM, the plant will be Navistar’s launch facility for Industry 4.0 manufacturing concepts, which include a digitized factory, connected machinery, lean manufacturing practices, and cloud analytics to enable predictive quality and maintenance.

Production at the facility began in January—with the International eMV Series electric truck as the first vehicle off the line in San Antonio. The purpose of the plant from inception was to have the capability to manufacture both electric and internal combustion engine powertrains on the same line. Navistar has invested more than $250 million in the nearly 1 million-sq.-ft. facility.

The OEM has also acquired a second property in San Antonio for an Advanced Technology Center to accelerate the implementation of emerging technologies in the commercial trucking space.

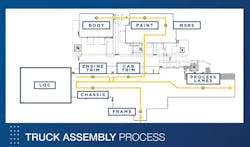

This gallery provides a detailed look of the truck assembly process at the new facility. Before starting the vehicle assembly process, all materials and components are delivered, stored, and distributed from the facility’s logistics center. Then, the truck assembly process simultaneously begins in two separate areas: the body shop and the general assembly line.

This article originally appeared in FleetOwner.com.

About the Author

Cristina Commendatore

Cristina Commendatore is the Executive Editor of FleetOwner magazine. She has reported on the transportation industry since 2015, covering topics such as business operational challenges, driver and technician shortages, truck safety, and new vehicle technologies. She holds a master’s degree in journalism from Quinnipiac University in Hamden, Connecticut.