New Year's Needs

Stephen Howe is employed by Tweddle Litho Company, a global provider of information development, management and delivery that has served the automotive and heavy vehicle industries for over 50 years.

Stephen is also a past president of the Automotive Training Managers Council (ATMC), a global, non-profit organization of over 60 member companies dedicated to recognizing training excellence and raising training standards in the automotive, heavy vehicle and related industries.

Depending on when you pick up this issue of Fleet Maintenance, you may already be well into 2006. No matter, it's not too late to make a New Year's resolution for increased fleet training. Some of you may be looking at new budgets from your proprietors or parent companies. Don't forget to consider training in your budget allocations!

A good way to start compiling your training needs is to create a matrix. Over the years, I have probably complained about maintaining our company's ISO/QS standards as much as anyone. One tool, however, with roots in ISO that I've always felt is valuable is the training matrix. This matrix requires you to periodically assess employee job requirements and determine the areas where skill and knowledge deficiencies may exist.

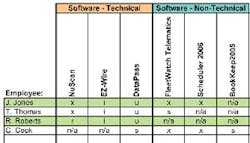

There are many ways to compile a training matrix. The method I use is shown in Figure 1. Employees are listed in the far left column, and job requirements are listed across the top. In the rows next to the employee names, you can use the following to identify the level of training required:

- x = Training completed and/or employee has mastered the job task.

- r = Training is required.

- u = Update training is required (for example, new diagnostic software for a tool you already use).

- i = Information only is required (for example, an updated instruction manual or new job aid).

- s = Secondary job task for employee; training would be required for the employee to move into a new job position or back up another person who currently performs that function.

- n/a = Job task is not applicable to this employee's position or function; no training is required.

In the example provided, I've only shown a couple of skill/knowledge areas. In larger fleets with many departments, I'm sure the matrix could have a few dozen columns!

After compiling the matrix, it will then be necessary to prioritize the training needs and make decisions on who gets trained when. This is particularly important when budget and/or employee time away from the job are issues. Along these lines, you may consider areas where cross-training, mentoring or coaching from one of your "experts" can take the place of training. Of course, this won't work for brand new technology. But in the case of an updated computer program, you may already have someone in-house who has mastered the program and can train others.

Some hot training issues for 2006:

- 2007 DIESEL EMISSIONS. Planning to purchase new (2007 model year) light- and medium-duty trucks with diesel engines? Keep in mind that any of these vehicles sold after October 1, 2006 will have to meet the stricter Environmental Protection Agency standards for diesel emissions. These engines are likely to have some major internal changes, as well as newer technology such as high-pressure common rail fuel delivery, electrostatic particulate traps, enhanced Exhaust Gas Recirculation (EGR) cooling.

- DIAGNOSTIC HARDWARE AND SOFTWARE. Finding fewer and fewer functions your old scan tool can support. Is the OEM or tool manufacturer continuing to support it? Most vehicle diagnostics are migrating to laptop computers, PDA tools or wireless systems. If this is the case in your fleet, training your technicians to use these tools is likely NOT an option!

- TELEMATICS SYSTEMS. On-board telematics systems are now being offered by some OEMs and aftermarket manufacturers. These devices use the Global Positioning System (GPS), on-board vehicle control module networks, BlueTooth or similar wireless technology and custom computer programs to allow fleets to precisely track vehicles, drivers and data. Training is likely required for the dispatchers, office personnel and/or maintenance managers who interface with these systems, as well as the technicians that may be required to service the hardware or periodically update on-board software.

I've focused mainly on technical training issues here, but don't forget to also look at your everyday tools, office software and soft skills that may need updating to increase productivity and customer satisfaction in the coming year!