How to establish a rapid repair assessment process

What’s worse than unexpected downtime to a fleet? It’s unexpected downtime that drags on longer than fleet and fleet customer expectations.

The problem is especially difficult if repairs must be made far from the fleet’s own network of maintenance facilities, and it has to rely on third-party maintenance service providers to get the vehicle in question back in service hauling freight.

Fleets and service providers, unfortunately, have different expectations when it comes to the definition of timely diagnostics and repairs. When this happens, delays in the repair process can heighten tensions and strain fleet-vendor relationships to the breaking point.

To improve on fleet-service provider relationships, TMC’s S.16 Service Provider Study Group has issued or completed more than a dozen such recommended practices (RPs) to improve on fleet-service provider relationships.

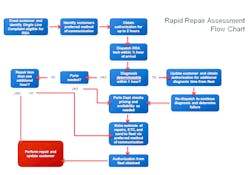

One of these is RP 1604, Rapid Repair Assessment, which provides basic guidelines for a service provider to implement and manage a rapid repair assessment workflow process in its operation. This process should enable a service provider to start diagnosis of a mission-disabling complaint within two hours of arrival and check-in. Check-in includes obtaining authorization for up to two hours of diagnostic time and determining the preferred method of communication with the customer.

The Diagnosis Phase

The RP states that after two hours of diagnosis, the service consultant should communicate the status of the diagnostic process with the customer. This communication should include customer authorization for more diagnostic time – if needed – and a specific time frame as to when the additional diagnostics should be completed.

If the diagnostics are completed at the two-hour mark, then a complete estimate for the repair – including needed parts, parts availability and estimated repair completion time – should be submitted to the customer. From this point, the service provider and the customer should be able to agree upon a repair plan.

The Assessment Process

The following items should be measured, monitored and reported to all involved on a daily basis when tracking the progress of the rapid repair assessment process, states RP 1604:

- Time stamp from the time the repair order is written to the time the diagnostic technician is dispatched onto the repair order for diagnostics.

- The actual time from when the diagnostic technician enters the repair order to the time the technician gives the information back to the service department to form a repair plan with the customer. It is also suggested to monitor the time waiting for information about parts availability and pricing.

- Information from Items 1 and 2 should be shared on a spreadsheet that includes the repair order number, customer identification and the results of the two-hour time windows with all departments and all people involved in the implementation and management of the rapid repair assessment process.

Implementation Guidelines

RP 1604 offers this advice for how a service provider should implement a rapid repair assessment process within one of its locations:

- Pick a well-monitored shift. No matter how many shifts are run or how many days the facility is open, a service provider should implement the rapid repair assessment process on the shift that is most monitored.

- Identify the technician who will be performing all the diagnostics on a specified shift. This technician should be one of the highest-trained technicians at the service provider’s location and possess good communication skills.

- Meet with all managers and review the policy and processes that will be put into place with a tentative start date. The parts department must understand the importance of quick turnaround, parts availability, parts pricing and to whom such information should go.

- Explain the procedure in detail to your diagnostic technicians. Let them know who their main contact is in both the parts and service departments.

- The technician will bill diagnostic time to the repair order, even if it is a large job that will need to be scheduled for additional repairs in the shop.

- Once the rapid repair assessment process is in place and working smoothly, the management team can then implement the process on other shifts and weekends. The key is to work slowly and manage the process.

Once the process has been implemented, customers will enjoy faster service, better communication and a friendlier experience each time they return to the service facility with a mission-disabling complaint.

Kenneth Calhoun is the outgoing chairman of TMC’s S.16 Service Provider Study Group. In February 2015, he was elected to TMC’s board of directors as its first service provider representative. He is also vice president of customer relations for Truck Centers of Arkansas (www.truckcentersar.com), a full-service dealership with headquarters in North Little Rock, Ark. TMC is North America’s premier technical society for truck equipment technology and maintenance professionals (www.trucking.org/Technology_Council.aspx). It is a part of the American Trucking Associations (www.truckline.com), the largest national trade association for the trucking industry.