While they may disagree on what manufacturer or type of lift is superior, one thing all vehicle lift experts can agree on is the need for annual inspections, as an improperly maintained lift can lead to vehicle damage and, even worse, serious injury or fatality.

"It's not a matter of if a lift is going to fail, but a matter of when," warns ALI President R.W. "Bob" O'Gorman. "It's a mechanical device, and all mechanical devices have got to be properly maintained and inspected."

Read more: Lifting strategies of the South PacificAnd Jason Matthews, product manager at Rotary Lift, notes that along with safety and longevity, there's revenue at stake. At the very least, it will cost a shop "over $1,000 a day that's lost when a lift is down," he offers. That alone is good reason to get a certified inspector into the shop every year to inspect them.

"The American National Standards Institute standard [ANSI/ALI ALOIM 'Safety Requirements for Operation, Inspection and Maintenance'] says, and has always said, that vehicle lifts are to be inspected annually. Period," emphasizes Steve Perlstein, president of Mohawk Lifts. And he agrees that "an experienced lift inspector" should complete the task.

ALI's new approach

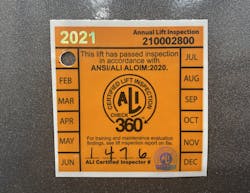

Through its Certified Lift Inspector Program, ALI tests and certifies qualified lift inspectors. These ALI Certified Lift Inspectors can inspect any lift. ALI encourages shops to demand a Check360 Certified Lift Inspection—a comprehensive examination of the lift structure, its electrical and mechanical components, training logs, operating instructions, and safety manuals. Only Check360 inspections are backed by ALI to meet all the requirements in the national lift safety standard. A passing lift receives an exclusive Check360 Certified Lift Inspection label featuring the program logo hologram, a serial number matching the inspection report, and the inspector’s individual ID.

Preparation makes perfect

It's important to note that shops must do a little prep work to ensure the inspector can get in and out as quickly as possible. First off, the shop should perform the necessary maintenance on lifts to ensure they pass.

Part of this process includes ensuring that each lift is properly labeled with its capacity label and safety placard before an inspection. Even if labels aren’t available, keeping the lift's bill of sale or owner’s manual on hand can work as an apt substitute, notes Buck Gasner, a certified lift inspector for DEKRA North America.

This element is particularly critical, as Gasner estimates that many lifts that fail their inspections do so not because of any technical problems, but because of improper documentation.

“People sometimes get angry when we say they fail for lack of a capacity label, but it’s [really] simple,” Gasner says. “How can I tell you if the lift is doing what it’s supposed to do if I don’t even know what the lift is supposed to do?”

Adding insult to injury with an improperly labeled lift is the process of reinspecting the equipment once its documentation has been corrected. With some inspectors traveling to shops within a specific timeframe, scheduling a reinspection can be more costly in time and money than a shop would prefer.

Additionally, making sure that all the necessary documents, including manuals and training records, are organized and accessible is a critical time saver, though one inspectors wish was followed more often.

“We ask for all these materials, and 99 out of 100 times, it’s the end of the day and the shop is still digging through filing cabinets," Gasner says. "If they take the time the day before to have that ready, that helps everything go much smoother as well.”

“We get asked a lot of times, ‘Can you mail me the label after I fix it?’ No, no, we cannot,” Gasner clarifies. “Those labels are treated like gold and serialized… So, the number one way to get recertified would be to come back and do a reinspect."

If bringing an inspector back around to the location is not an option, a shop must be able to build a watertight paper trail to prove their compliance. This means having the first lift inspection that displays any problems and then the invoice or work order for the part or label that needed replacement.

“And at that point in time, if an AHJ (authorities having jurisdiction) has a question, [the shop] can say, ‘Yes, here’s my inspection report that showed [the lift] had this deficiency, here’s documentation that this deficiency was taken care of.’ And at that point, you’re covered," Gasner says.

About the Author

Alex Keenan

Alex Keenan is an Associate Editor for Fleet Maintenance magazine. She has written on a variety of topics for the past several years and recently joined the transportation industry, reviewing content covering technician challenges and breaking industry news. She holds a bachelor's degree in English from Colorado State University in Fort Collins, Colorado.