“There’s more riding on your vehicle lifts than trucks,” says Ron Lainhart, says parts and service manager for Rotary Lift, the leading brand of vehicle lifts and equipment designed to increase technician productivity (www.rotarylift.com). “Vehicle lifts support your business.

“Productivity studies conducted by fleets and truck maintenance providers have found that a single vehicle lift can add $100,000 or more to the bottom line in terms of annual profits or reduction in labor overhead. If a lift is down for repair, productivity in that bay can be cut in half.”

To keep vehicle lifts operating properly, good maintenance and inspection practices are crucial, he says, and offers the following advice:

1. Read and follow the guidelines in the lift’s owner’s manual. Maintenance and inspection requirements vary for different styles and brands of vehicle lifts. The owner’s manual will cover the specific needs of each lift.

2. Schedule annual lift inspections for all vehicle lifts. This inspection should be performed by a factory-authorized technician. The lift manufacturer can recommend authorized service companies in your area.

In a few months, the first group of Automotive Lift Institute (ALI) Certified Lift Inspectors will be available to perform lift inspections. The ALI is a trade association that provides manufactures of automotive lifts throughout the U.S., Canada and North America with the most current regulatory information available.

3. Whether maintenance is performed in-house or by an outside service company, be sure to insist on genuine OE replacement parts. OE parts were designed by the lift manufacturer to original design specifications.

Aftermarket parts are reverse-engineered and may not use the same materials or incorporate the latest design changes, Lainhart notes. ALI recommends using OE parts to ensure proper fit and function. Using aftermarket parts on an ALI-certified lift may void that lift’s certification.

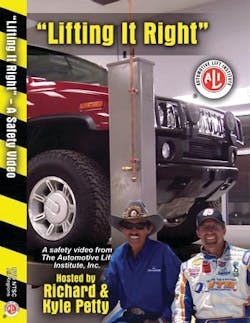

ALI offers general lift maintenance and inspection guidelines in a variety of materials, including the Lifting It Right training manual and DVD which features racing legends Richard and Kyle Petty discussing the importance of inspecting all automotive regularly and proper lifting techniques. These materials are available directly from ALI or through its members. Visit ALI’s website at www.autolift.org for details.

About the Author