Fleet Advantage offers free safety audits for Brake Safety Week

Brake-related violations represent the biggest share of all out-of-service vehicle violations cited during roadside inspections, and Fleet Advantage is looking to cut those down by offering complimentary Fleet Audits in conjunction with the Commercial Vehicle Safety Alliance’s (CVSA) Brake Safety Week, scheduled for August 21-27.

Brake Safety Week is an annual commercial motor vehicle brake-safety inspection, enforcement, and education initiative conducted by law enforcement jurisdictions in Canada, Mexico, and the U.S. During Brake Safety Week, inspectors conduct their usual North American Standard Level I and V Inspections and capture and report brake-related data to CVSA before releasing results in the fall.

The role of Fleet Advantage Fleet Services Group

Fleet Advantage’s complimentary audits include dedicated fleet services technicians who are thoroughly familiar with specifications, fleet portfolio, and operational strategies. They monitor and correct fleet performance issues such as brake systems and adjustments, and when enlisted for a long-term period, provide these services throughout the extended life cycle of each fleet vehicle.

The Fleet Services professionals who will perform these audits are typically dispatched for on-site shop inspections and remedies, where they monitor and evaluate OBC data, apply proper metrics to render vehicle performance, and monitor and report various fuel, maintenance, and repair metrics. Afterwards, they automatically alert clients if adverse performance issues are detected and provide them with best practices to mitigate any issues.

Fleet Advantage’s Fleet Services experts and technicians are also versed in various Federal Regulations (OSHA, DOT, FMCSA, EPA) to verify on-site compliance. When fully engaged, they offer monthly reports of each fleet’s performance on a per unit basis, including:

- Technician Efficiencies: identify inefficiencies and provide applicable training

- Tire programs (biggest M&R expense): provide analysis and best practices for each operation

- Preventive Maintenance intervals and compliance

- Additional safety tips all fleets and personnel should be aware of

Matthew Wiedmeyer, director of Fleet Services for Fleet Advantage provided some Brake Safety Week preparation tips on the company website. He noted the main issues inspectors check for include:

- Loose or missing parts

- Air or hydraulic fluid leaks

- Torn or damaged linings, hoses, pads, drums, or rotors

- Other faulty brake system components

He also added maintenance technicians should be certified to inspect and repair brake components in accordance with 49 CFR – Part 396.25 “Brake Inspector Qualifications” Form 508.

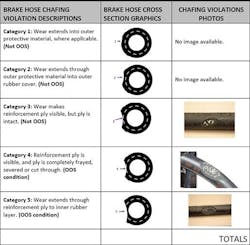

Wiedmeyer stressed that brake hose chafing, which may not result in an out-of-service violation, should not be ignored. There are five levels of severity, according to the CVSA. Images for reference are provided below: