Cummins and DuPont partner to use filter technology to supply critical material for N95 respirator masks

As the COVID-19 pandemic spreads across the globe, Cummins Inc. and DuPont are helping address the nation’s shortage of N95 respirator masks. Cummins’ NanoNet and NanoForce Media technology, which uses DuPont’s Hybrid Membrane Technology (HMT), can typically be found in air, fuel, and lube filtration products used in heavy duty diesel engines to prevent long-term engine wear, but also can be used in the N95 respirator masks worn by healthcare professionals to filter harmful airborne particles that can spread COVID-19.

The need for N95 masks has skyrocketed in recent weeks in response to the COVID-19 pandemic. Many of the world’s leading mask manufacturers are in need of the critical materials to assemble the mask and are struggling to meet demand.

“Cummins is re-evaluating our supply base and manufacturing capabilities to identify how we can support our healthcare professionals who rely on critical personal protective equipment to do their jobs,” said Amy Davis, vice president of Cummins Filtration. “Our NanoNet Media can fill a key supply void and help address the mask shortage facing the United States and other countries around the world.”

The first mask prototypes using Cummins’ donated media were assembled by University of Minnesota teams in March as part of an initiative to provide masks to M Health Fairview and other Minneapolis-based healthcare systems. As the COVID-19 outbreak escalated, the University of Minnesota realized their supply of N95 masks to protect healthcare workers would potentially run out in a matter of weeks. To address this challenge, a team of designers, engineers, chemists, surgeons, anesthesiologist, and apparel and clothing experts from the University of Minnesota’s Institute for Engineering in Medicine; Medical School; College of Design; College of Science and Engineering; and Center for Filtration Research Consortium (CFR) came together to address this projected shortage of critical personal protective equipment.

“The first thing we recognized from our experts in the Center for Filtration Research, who work directly with Cummins, is that not all filtration materials are created equal and that the Cummins material is an excellent alternative,” said Jakub Tolar, campus health officer and Medical School Dean at the University of Minnesota. “We are tremendously grateful for the generous donation from Cummins of their filtration materials toward our mask effort. Since the arrival of the filtration media, we have been able to make rapid progress, and we now believe we have several viable mask options, including both a disposable and re-usable option. These designs show real promise in keeping our healthcare workers safe should standard medical supplies of N95 masks no longer be available.”

The project also aims to provide open source instructions that other healthcare systems and groups can use to create their own respirator masks.

While DuPont’s innovative and unique Hybrid Membrane Technology (HMT) is typically integrated with Cummins’ synthetic fibers to protect sensitive engine components, it has multiple other applications that can include filtration media used in N95 respirator masks.

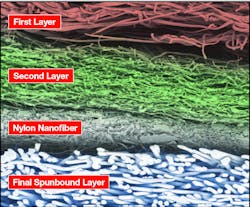

DuPont’s Hybrid Membrane Technology goes beyond the limits of traditional semi-porous or nonwoven membranes for air and liquid filtration. Made using a proprietary spinning process, the hybrid technology materials are comprised of continuous sub-micron fibers. The end result is a “membrane-like” sheet structure that balances breathability and high filtration efficiency of particulates.

“We are proud to make our advanced technology available to help protect more caregivers on the front lines of this global health crisis,” said HP Nanda, global vice president and general manager, DuPont Water Solutions. “We thank our partner Cummins for transitioning the use of its production line to help address the global shortage of N95 mask materials, and we thank the experts at the University of Minnesota for their leadership in testing and designing several mask options for the benefit of many healthcare systems. By working together – and innovating new applications of existing technologies and materials – we hope to slow the spread of this terrible virus.”

The N95 designation means the respirator can block at least 95 percent of particles from entering the wearer’s nose and mouth. When Cummins’ NanoNet Media was tested using an industry standard testing method, it exceeded the performance requirements for N95 designation. Cummins’ manufacturing facilities have since provided media samples to mask manufacturers across the globe to test its effectiveness.

While products featuring Cummins’ media will need to be vetted and approved by the National Institute for Occupational Safety and Health (NIOSH), the company is preparing to do its part to help relieve the burden facing the healthcare industry. “We’re working as quickly as possible with healthcare regulators and other partners to help certify products with our materials, and prepare our manufacturing facilities to meet demand,” Davis said.

Mask manufacturers interested in learning more about Cummins’ media technology can visit cumminsfiltration.com/respiratormedia.