TMC: VMRS Adapts to Standardize Predictive and Prognostic Maintenance Alerts

From its inception, the Vehicle Maintenance Reporting Standards (VMRS) has been a collaborative effort involving a diverse group of contributors representing the equipment maintenance industry. Original equipment manufacturers (OEMs), parts manufacturers, fleets, service providers and fleet maintenance software firms have all played a part in helping to expand the scope and acceptance of VMRS. It’s been a team effort for more than 50 years and continues to be going strong year after year.

In recent years, ATA’s Technology & Maintenance Council (TMC) — the custodian of VMRS — has added codes for crash avoidance, lane departure, camera monitoring systems, adaptive speed control and most recently electric vehicles, all with the help of folks from the VMRS user community. VMRS continues to reflect new technologies that are developed for equipment and equipment maintenance and will continue to do so for many years.

The torrent of activity surrounding telematics services has prompted TMC to begin considering a new class of VMRS coding to address predictive and prognostic maintenance alerts. These codes will standardize the electronic maintenance alerts back office systems communicate to vehicles when services are anticipated.

Brian Mulshine, Navistar, started the conversation in September 2022 during the VMRS Codes Task Force meeting at TMC’s 2022 Fall Meeting in Cleveland. The idea is to create a common language/schema in VMRS to be leveraged by vehicle OEMs, engine manufacturers and component suppliers to digitally communicate “predictive/prognostic maintenance alerts/requirements.”

VMRS coding has traditionally been used to record maintenance/repair data after the service event takes place. Parts and labor are usually entered by the attending technician or manager, using some type of maintenance software or filling out a work order by hand.

Related content: Fleetio adds VMRS Code Keys to its maintenance data categorization capabilities

However, with the advent of artificial intelligence (AI) and machine learning, things in the maintenance world are changing. Vehicles, equipment and/or components now send diagnostic information directly to the maintenance department. There needs to be an agreed upon method of interpreting and implementing the received data, and many believe VMRS is the perfect method. It’s been the “universal” maintenance language for more than 50 years and continues to prove to be flexible and adaptable.

VMRS Code Keys are data elements or data “buckets” that hold individual codes of just about anything pertaining to maintenance, repair and vehicle specification. Think of a Code Key as an individual book in the VMRS library. There’s a book for repair reasons, work accomplished, part position, part identification, etc. Most industry professionals are familiar with the VMRS nine-digit Component Code Key 33, but VMRS is comprised of 65 separate Code Keys each containing codes related to various areas of equipment maintenance and equipment designation. There are Code Keys that contain codes for designating labor, part failures, equipment attributes and much more.

As technology evolves for improving maintenance of vehicles, most OEMs are working on “data driven” maintenance to improve the customer’s experience. New forms of maintenance include condition-based maintenance (CBM), sensor driven and dynamic (advanced) PMs, and methods of leveraging real time fuel economy to adjust intervals.

Mulshine has brought in many interested parties from various areas of equipment maintenance to help develop this new standard — OEMs, fleet software providers, engine manufacturers and fleets have all expressed an interest in adding the new Code Key to VMRS. They all agree on the need for a common language for indicating the required needed service. The codes can be used across all vehicle/engine OEMs and component suppliers to digitally communicate predictive and prognostic maintenance and repair requirements.

Multiple vehicle and engine manufacturers have data currently or becoming available soon that designates remaining useful life (RUL) of certain components and/or maintenance due soon. Since no standard is currently available, fleets are receiving this information by email with attachments, customers are then expected to take the data and enter in their systems, the proposed VMRS Code Key will include new codes that will include this information offering fleets a way to communicate and receive this important data.

Related content: Equipment coding for the future

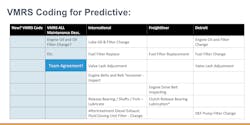

The new VMRS Code Key is expected to include service requirements that are due soon, past due and need replaced soon. Several examples are:

• Past due – Oil change, fuel filter, lube driveline. • Due soon – Valve lash adjustment, DEF filter. • Needs replacement soon – Air dryer, fan belt.

Mulshine has put together a list of service requirements from several OEMs that will be the basis for the code descriptions in the new Code Key and like the existing VMRS Code Keys there is always room for expansion.

Another proposal is to expand existing VMRS Code Key 52: Part Status Codes to include required elements for predictive and repair dispositions. The code key would be renamed “Maintenance and Part Status” reflecting the new proposed VMRS Code Key. Examples of new codes are – “due soon, past due, service immediately and request performed.”

New VMRS Code Key proposals are subject to the same balloting and appeal development process as any other TMC Recommended Practice. They must be first developed and approved by the VMRS Codes Task Force, next reviewed by the appropriate Study Group Chairman and TMC staff, then put up for balloting to the entire TMC membership. If balloting is successful, and there are no appeals following the balloting approval, the Code Key will become part of the VMRS library, collectively entitled, TMC RP 802, TMC/ATA Vehicle Maintenance Reporting Standards (VMRS).

The Task Force is working on the proposed additions this summer and expects to send the new material for balloting following TMC’s 2023 Fall Meeting in Cleveland, Sept. 17-21.

VMRS has always reflected the latest in technology when it comes to maintaining many types of equipment, it’s been the industry standard for more than 50 years and will continue its mission on into the future. The industry is undergoing rapid change and VMRS promises to keep current and relevant to its many users no matter what the future brings.