Tech Tip: Solve communication issues without an oscilloscope

Solving communication failures is a difficult task for any technician, and only a small percentage of technicians are proficient with Oscilloscopes, a common tool for pinpointing such issues. Luckily, a more intuitive method is available to reduce the difficulty in determining the cause and location of a communication error, resulting in a decreased diagnosis time.

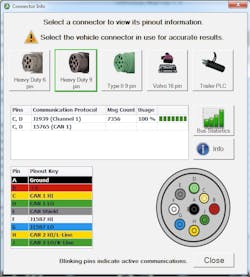

Historically, oscilloscopes were the primary tool to determine what a healthy vehicle communications bus looked like. By using this difficult tool, a well-trained technician could determine if there was a problem on that network. With the progression of advanced in-shop diagnostic and repair tools like Noregon’s JPRO Professional, technicians can use a Bus Statistics screen to simplify the process. The Bus Statistics feature gives technicians a visual representation of which modules are online and which ones are communicating. Ultimately, this feature allows technicians to make accurate diagnostic choices by recognizing which modules are communicating properly.

Users launch Bus Statistics from multiple locations in JPRO, including the Connector View screen. This screen shows an image of the Diagnostic Link Connector (DLC) in question to ensure the technician knows which connector he or she is working with. The color-coded, animated diagram on the screen blinks to indicate active traffic on that particular pin.

Using Bus Statistics

Now that you know what is included in Bus Statistics, and how to launch it, we can look closer at how to utilize the feature to solve a communication problem. Bus Statistics is a useful tool for determining network integrity, as it illustrates which modules are actively communicating. If the Bus Statistics feature shows no instance of a major electronic control unit (ECU), such as the engine, transmission, or ABS system, you will have a starting place for performing diagnostics, which will help determine the root cause of the communication failure. It is vital to fix all communication errors and then perform entire vehicle diagnostics once every ECU is properly communicating to fix the entire vehicle.

Information provided by: NOREGON