How to bust rust and corrosion on your trucks and trailers

Rust—and corrosion overall—can wreak havoc on fleet assets such as trucks and trailers, with the potential to compromise safety and uptime, while also increasing repair and replacement costs. And all it takes to develop is the right material, like untreated carbon steel, placed in the right conditions—outdoors in the rain—over a certain amount of time. This process weakens and ruins whatever it touches, reducing the toughest steel constructs to crumbling reddish-brown flakes.

For more on protecting against corrosion:

The war against rust has been waged since at least the Iron Age, with each fleet still fighting its own battles to varying levels of success. If you feel like you’re on the losing side, fear not. According to the experts we spoke with, there are plenty of rust-busting weapons fleets and shops can deploy to turn the tide. And they explain in detail how to use those to properly maintain your truck and trailer components, which are most susceptible to rust and corrosion. But first, let’s explain exactly how metal’s mortal enemy works.

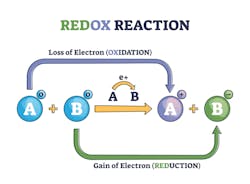

Corrosion is the electrochemical process by which certain metals and non-metals deteriorate as a result of oxidation, or when a surface is exposed to air or chemicals. At the molecular level, this oxidation-reduction (redox) reaction steals an electron from the material and gives it to the environment, so it’s kind of like a tax from Mother Nature. Discoloration varies by substance and catalyst. For example, a battery terminal may develop a green or white chalky layer when the sulfuric acid reacts with the copper terminal. If the sulfuric acid is hot, a blue hue may appear. Either way, conductivity diminishes, and you might experience slow cranking, reduced battery life, or possibly total failure.

Rusting is a type of corrosion related to iron oxidation. It occurs in the presence of air and moisture. Thus, rusting develops as an orangey-brown growth on the surfaces of iron and its alloys. Salts, such as the ones Northern roads are covered in all winter, accelerate the process by essentially supercharging the negative ions as the molecules break down.

In a perfect world, fleets could keep all their trucks, trailers, and shop tools in a perpetually clean, dry environment, and they would never come into contact with moisture or chemicals. In the real world, of course, that isn’t happening. The good news is that there are several ways to slow or stop corrosion, ranging from preventive maintenance and cleaning to coatings and products that thwart rust and corrosion.

Learn to coat

First and foremost, fleets must remain vigilant to keep things clean and protected. Technicians should regularly inspect for rust, pitting, or damage to higher-risk components like wheel ends and brakes, as well as the undercarriage, suspension, and frame. Paint starting to bubble or peel is an obvious sign.

Then, well-timed cleaning is essential.

“Regularly wash and thoroughly dry vehicles to remove road salts, dirt, and other corrosive substances,” said Scot Reeder, senior product manager at STEMCO. “Apply wax or ceramic coatings to protect the paint and metal surfaces from corrosion. Use anti-corrosion sprays or treatments on vulnerable areas such as the undercarriage and wheel wells. You can also apply rust inhibitors to metal parts to prevent rust formation.”

Fleets can also preemptively strike against rust and other corrosion during the spec’ing stage by choosing truck and trailer bodies and parts, like hitches, made from galvanized steel. Galvanization coats the steel or iron components with zinc. This brave element serves as the sacrificial anode and takes the brunt of moisture and oxygen, and will corrode before the underlying steel does. Through a process called cathodic protection, a zinc patina layer forms.

It can have a huge slowing effect on corrosion. The International MY2025 HV Series, for example, uses a double-sided galvanized steel and anti-corrosion coating for its cab. Andy Hanson, International vocational marketing director, noted the fortification allows the cab to withstand 1,000 hours of exposure and the rail 2,000 hours.

Galvanization does add cost, so you may choose other coating options.

If operating in harsh cold-weather environments, you may want to consider adding an underbody coating. This area is regularly splashed with melted snow and ice that’s laden with chloride from deicers.

“Chassis are also less visible and more difficult to clean than the rest of the vehicle, making it more likely that corrosion deterioration could creep up on fleet managers unexpectedly,” said Julie Holmquist, content writer for Cortec, a developer of corrosion-control technologies.

Suspension OEs also offer their own coatings. SAF-Holland has made its anti-corrosion coating, called Black Armour, standard for many years. SAF said the eco-friendly “protective skin” guards against moisture and anti-icing chemicals while not shrinking or peeling.

Hutchens Industries, meanwhile, fights corrosion at the design phase by engineering its 9200 with “C” channel frame rails. This design removes areas on the suspension that would collect salt and rust faster. Hutchens also sells “hot-dipped” galvanized versions.

Fleets that want the convenience and low VOC benefits typical of water-based coatings may opt for something like Cortec’s CorrBarrier. The company also offers VpCI-398, a solvent-based sulphonate version for those who desire heavier-duty protection. VpCI stands for Vapor Phase Corrosion Inhibitor.

Throughout the winter season, it’s important for fleets to regularly wash their vehicles. This seemingly simple step is more scientific than you’d think. According to Holmquist, fleets should consider adding a flash corrosion inhibitor to their detergent for extra protection against flash rust during and shortly after washing.

“VpCI-406 is one phosphate-free cleaner that includes a flash corrosion inhibitor,” Holmquist said. “It can be metered into automatic washes or power wash equipment.”

For vocational trucks, fleets should also consider protecting things like truck beds, snowplows, and other hydraulically powered equipment.

“VpCI-396 is a one-component, corrosion-inhibiting urethane coating with 2H pencil hardness for high scratch resistance,” Holmquist said. “For even longer-lasting durability, it is best to prime the surface with a corrosion-inhibiting epoxy coating such as VpCI-395 first. This creates a stronger coating system with a durable base that continues to protect the metal, even when the topcoat wears away over time and needs to be reapplied.”

Armor Protective Packaging is another company that specializes in rust prevention products. The company’s Dry Coat Rust Preventative is a water-based liquid that creates a clear protective coating and dries to the touch within 30 minutes of application at ambient conditions. It can be a beneficial preventive measure in shops dealing with high humidity.

“Our Dry Coat is best applied in a trigger spray bottle,” said Chris Elias, sales and marketing director at Armor Protective Packaging. “It is safe to use on ferrous metals and stainless steel, and will not harm most elastomers or plastics. It protects for up to one year for items stored indoors.”

Protecting the trailer

Each of the commonly used materials for trailers—stainless steel, galvanized steel, and aluminum—offers varying degrees of corrosion resistance. Even aluminum can corrode under certain conditions, even though it will not rust.

Fleets should think about where their trailers are stored and utilized to determine the level of corrosion resistance they should spec for.

“In some cases, lower corrosion resistance is acceptable if the trailer is not exposed to the aggressive road deicing chemicals seen in colder, harsher climates,” said Tim Schmeits, director of reefer product engineering at Great Dane. On the other hand, exposure to road chemicals could warrant a higher degree of corrosion protection. “Coastal areas may also incur more corrosion due to the proximity to salt water,” Schmeits added.

What should fleets be focused on when spec’ing and evaluating trailers?

On aluminum flatbed trailers, there are a few areas that are more susceptible to corrosion.

Mark Sabol, platform product manager at East Trailers, said these include: “the air tanks and brackets, the area between the fifth wheel plate and main beam, the area where suspensions attach to the main beam, and the landing gear mounting area.”

On combo flatbed trailers, which incorporate a combination of steel and aluminum, Sabol said corrosion may occur where the floor crossmembers attach to the main beam of the trailer.

“To avoid corrosion, be sure the manufacturer uses a barrier to separate the dissimilar metals,” Sabol said. “This barrier can be paint or another type of isolator that will keep the dissimilar metals from touching. For instance, East Trailers installs an HDPE (High-Density Polyethylene) barrier between all steel and aluminum parts wherever they meet each other.”

When it comes to dry vans and reefers, there are two general categories of corrosion to contend with. One is more worrisome than the other.

“Generally speaking, when you can see surface rust, you can take care of it,” said Brian Hanlon, product manager for dry vans at Wabash. “What we worry about is rust and corrosion in areas you can’t see, especially structural areas.”

When spec’ing dry vans, Hanlon recommends paying close attention to the construction of the “crossmember to base rail connection” and the “coupler to base rail connection”. Those areas can be difficult to inspect unless the trailer is taken apart. Thus, those areas need to not only be stout, but also resistant to corrosion.

“Connections with dissimilar materials are where you’ll see galvanic corrosion,” Hanlon said. “On the crossmember to base rail connection, you typically have an aluminum base rail and carbon steel crossmember. There may also be backing tape, but that’s only good for so much.”

This is one reason why Wabash only uses a steel bolt as a connector. The typical alternative, an aluminum rivet, is susceptible to creating “hidden” problems, according to Hanlon.

“If an aluminum rivet corrodes from within, the head on the outside looks okay, but you don’t know what’s happening on the inside,” Hanlon explained. “Aluminum is also much more reactive than steel. When you use a steel bolt, the most reactive material is the aluminum base rail. That’s very large and easy to see on the outside. You’ll easily see discoloration if corrosion is starting, but it won’t fail. When you’re dealing with an aluminum rivet, on the other hand, you typically won’t see that corrosion and potential failure coming until it’s too late.”

Another area of a dry van to pay close attention to is the kingpin through the upper coupler. This area must maintain its integrity, but it can also be difficult to see. Hanlon recommends spec’ing for maximum corrosion resistance.

“Some manufacturers galvanize the entire structure, including the kingpin,” Hanlon said. “But galvanizing is a high-heat process that could soften the kingpin, so Wabash galvanizes the entire upper coupler, but not the kingpin. Instead, we weld the kingpin to that galvanized upper coupler and add sacrificial zinc locks inside the cavity. Zinc is highly reactive, so it will take all the moisture, and any corrosion will happen on those zinc locks, leaving the coupler intact.”

Even when spec’d with the right coatings, trailers need regular maintenance to ensure a less corrosive existence.

“Always inspect areas where dissimilar metals meet,” East Trailers’ Sabol said. “Keep those areas clean and free of road debris. If an isolator or barrier has been damaged or lost, we recommend repairing or replacing it to keep the corrosion at bay.”

As important as timely cleaning is, Hanlon discourages power-washing. (They are called dry vans, after all.)

“Trailers are waterproof, but not watertight,” said Hanlon. “You never want water creeping into little crevices. And if you’re cleaning with chemicals, read the product label because some of those products require a specific dilution. You’re asking for trouble if you introduce acidic materials and can’t control where they go.”

It’s also important to understand the types of products a given trailer is hauling. Some cargo, such as batteries, can off-gas. That could lead to corrosion or rust forming on the inside of the trailer.

“The good thing is you can see that,” Hanlon said. “You may see corrosion forming on roof bows and logistic strips. If you see any surface rust, you probably need to figure out some better ventilation.”

Gemplers also offers a suite of rust-combating products. Rust Remover dissolves rust to provide clean, bare metal. Rust Converter converts rust into an inert, protective coating that shields the metal underneath from exposure to moisture, preventing further rusting.

So, which one is the right one for a shop to use?

“Since Rust Converter forms a protective primer coating on treated metal, it isn’t what you want when you are looking for the final finish of the object to be bare metal,” said Devon McWilliams, systems support and product tech specialist at Gemplers. “It also isn’t suited to objects with close-fitting moving parts that might be stuck together as the coating dries. If the item can be taken apart, however, Rust Converter could be applied and then the item reassembled once dry. It is also important to note that Rust Converter coating is not heat- or chemical-resistant, so it can’t be used on parts like mufflers or inside fuel tanks.”

Concerning Rust Remover, it’s not a practical option for large objects. “That’s because the rusty object must be submerged in Rust Remover for it to work,” McWilliams explained.

It should be noted, McWilliams added, that neither product can restore the structural integrity of severely rusted parts or equipment. But to clean up some tools and parts with a normal level of rust, they can be very effective and easy to use.

About the Author

Gregg Wartgow

Gregg Wartgow is a freelancer who Fleet Maintenance has relied upon for many years, writing about virtually any trucking topic. He lives in Brodhead, Wisconsin.