There’s a prevailing theory out there that electric trucks are going to save the world and their adoption must be accelerated. Instead of pumping oil from the earth and converting it into energy—and as a result creating the harmful emissions that the United Nations warns will create climate catastrophes ranging from hurricanes to droughts—these battery-powered trucks can run on renewable resources like solar and wind power, all while creating zero emissions.

And because EVs have fewer moving parts, they are expected to require less maintenance. That’s important as maintenance operations struggle to find technicians to work on vehicles in general. Tack on the benefits to drivers—quieter, cleaner operation that doesn’t cause fatigue-inducing vibrations—and there’s a lot to be excited about.

The problem is that there’s an equal or greater amount of concerns. Electric trucks cost more (even with subsidies and incentives), don’t travel as far on the road or perform as well off it, and require major infrastructure changes. On top of that, no one really knows what the return on investment will be.

In testimony to Congress, Andrew Boyle, the new chairman of American Trucking Associations, said converting the nation’s diesel trucks to electric “would require a $1 trillion investment, which ultimately would flow to consumers,” adding that due to less capacity, lower ranges, and high charging times to haul the same freight, the industry would need “far more trucks” that cost two to three times as much as a comparable diesel truck. He pleaded that “we can’t allow unrealistic timelines…and technically unachievable regulations to set trucking up for failure.”

That’s just a sampling of the overarching issues. The dark side of commercial vehicle electrification is vaster than many are willing to admit—and likely obfuscated by some of those who staked their time, money, and reputations on its success. States and OEMs have also planned phase-out dates for diesel before EV technology has even proven itself. In short, the current push toward electrification oftentimes feels more like a shove. And while there’s no denying the potential of commercial EVs, accelerating their use in something as delicate and vital as the supply chain may lead society down a dark road indeed. Here we intend to shed some light on a few of the many reasons why the nation’s current electrification strategy should be reconsidered.

Government pressure and uncertainty

Long term, the Department of Energy declared the U.S. “must eliminate nearly all greenhouse gas (GHG) emissions from the [transportation] sector by 2050,” keeping in line with the Paris Agreement, which President Donald Trump pulled out of in 2017 and Joe Biden rejoined almost immediately after his inauguration in 2021. Trump said the deal imposes “draconian financial and economic burdens” on the U.S., while Biden said the global agreement would “help us all avoid catastrophic planetary warming.”

By 2030, the Biden administration aspires for EVs to comprise half of all new vehicles sold, but if Republicans take back the executive branch after the 2024 election, that plan could be stymied. Trump did pull back many emissions standards while in office, and meeting those standards is a primary reason many fleets are even entertaining the costly, time-consuming proposition of electrification.

Many would likely continue their CEV plans with the GOP in office, simply to do business in California. The California Air Resources Board (CARB) is the most aggressive on promoting CEVs and eliminating ICE, banning the sale of medium- and heavy-duty fossil fuel trucks in 2036. Starting next year, CARB is forcing high-priority fleets—defined as “entities that own, operate, or direct at least one vehicle in California, and that have either $50 million or more in gross annual revenues, or that own, operate, or have common ownership or control of a total of 50 or more vehicles (excluding light-duty package delivery vehicles)”—to make at least half of all their new vehicle purchases zero emission and 100% by 2027.

There has been some pushback recently on these plans. After previously following California’s lead, Connecticut Gov. Ned Lamont has reversed course on banning gas-powered vehicles in his state by 2035.

“The tide is turning as state officials across the country wake up to the reality that California’s electric-truck mandates are bad policy that carry serious political consequences,” ATA President and CEO Chris Spear responded, adding that “California’s sure-to-fail approach is not the only option.”

Spear reasoned that a better strategy is “ensuring the necessary infrastructure is in place and allowing for a range of technological solutions to prevail, rather than one-size-fits-all mandates.”

In another broad move to protect the environment, Biden’s Interior Department has placed a moratorium in Minnesota on mining cobalt, needed to make the large lithium-ion batteries used in electric trucks, and other metals. The Republic of Congo currently supplies a majority of the world’s cobalt, which it sends to China to refine and make batteries. The mines require the cutting down of millions of trees, which naturally remove CO2 from the atmosphere, and extraction of the toxic metal is done by child slaves, according to researcher and anti-slavery activist Siddharth Kara. The International Energy Agency (IEA) expects global demand of cobalt to increase 60% as a result of the Paris Agreement. Maybe the Congolese children can get the UAW to negotiate a higher wage than the alleged $2 a day they get now?

Perhaps the climate situation is so dire that severe, authoritarian measures must be executed and underdeveloped countries must be plundered. That does not change the fact that to stay financially viable, fleets need reliable, road-tested equipment to make their razor-thin margins. And right now, there are simply too few electric trucks out there to extrapolate success at scale and to justify the current timelines.

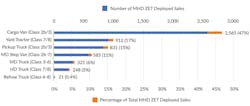

According to CALSTART data, the total number of medium- and heavy-duty zero-

emission truck deployments in 2022 constituted 0.3% of the total 1,186,966 Classes 2b-8 deployed sales. The 3,510 ZET units sold did constitute a 78% increase over the previous five years, but that’s simply not good enough to build confidence.

Tesla founder and CEO Elon Musk has been quite upfront on how “making one of something is easy,” while “making lots of something consistently that’s going to last a long time is extremely hard.”

No example proves this more than the Tesla Semi. You’ve likely heard someone joke that it’s been coming out next year for the last five years. It was announced in 2017, and production was set to begin in 2019. It’s now being fleet tested. The impressive early results suggest more time equals a better product.

Another example of EV success, the Freightliner eCascadia, has years of real-world experience. Schneider National, the seventh largest for-hire fleet, has 92 eCascadias that just passed one million miles of freight hauled. Volvo’s VNR Electric and Mack’s LR Electric refuse truck have also seen steady work on a small scale, as have Kenworth’s and International’s medium-duty trucks. Mid- and large-sized fleets’ pilot tests have also shown there is absolutely a place for electric trucks.

The question is if and when CEVs should comprise entire fleets. Of the 500,000 or so for-hire carriers, more than 80% are considered small. For electrification investments to scale and thus reduce their price to make them more accessible, small fleets will need to be persuaded with results, not strong-armed with regulations.

Building confidence and infrastructure

Some Tesla Semis can now be seen making deliveries for PepsiCo, and range data from the North American Council on Freight Efficiency Run on Less: Electric Depot program is a reason for optimism. While many Class 8 EVs struggle to get 200 miles per charge, the Tesla Semi recorded a 410-mile clip on one charge and 1,076 miles in a day. This was due to opportunity charging, which won’t fill the battery all the way but capitalizes on a lithium-ion battery charging as quickly up to 80% as from that point to a full 100%.

“It’s nice for them to show these big numbers, but you can’t get delivery yet,” NACFE Executive Director Mike Roeth told Fleet Maintenance.

Even so, the technology is trending in the right direction. The 18-day study revealed that deploying and scaling electric trucks at larger depots “are more possible than we thought,” Roeth said.

The former Cummins engineer is an unabashed advocate for improving efficiency and reducing emissions across the transportation industry, and is also as honest about EVs’ shortcomings as he is eager to laud their benefits. Roeth was most positive on lighter-duty deployments.

“The smaller the truck, the better the total cost of ownership is because you don’t have these ginormous batteries and really fast, expensive fast chargers and all that,” he said.

This was NACFE’s fourth foray into collecting truck efficiency data through real-world testing, and the second with commercial electric vehicles. The nonprofit has also produced several in-depth confidence reports since being founded in 2010, and the real-world depot test was a way to grow industry confidence in electric trucks as early adopters scale up units, charging infrastructure, training, and maintenance.

Roeth compared a truck depot’s energy usage to that of an NFL stadium, and building up infrastructure to get enough energy to charge several heavy-duty trucks even once has proven difficult.

“That’s taking much longer than these 10 fleets expected,” Roeth said, “and everybody else trying to do this is finding the same thing.”

If a fleet of 100 were to adopt 10 electric trucks, it could find the capacity, he said, but it would have to have serious discussions with their energy provider for another 20 to 30 trucks.

Those discussions need to be had well in advance of actual deployments, noted Rich Mohr, SVP of Americas for ChargePoint, one of the leading end-to-end providers of charging infrastructure.

“I haven’t run into a problem with a utility saying they don’t have power available for a site,” he said. “What the utilities really need to understand is how much infrastructure [a depot will need] to anticipate over the next five years so they can prepare for that.”

For a couple of buses or heavy-duty trucks, Mohr, the former CTO of Ryder, said an average of 1 megawatt, the equivalent to powering the Empire State Building for one day, would be required.

“Imagine how long it takes to prepare a city utility for building a new skyscraper,” he said. “That’s years of work to understand that that power needs to go there. That’s the biggest risk in the entire electrification model right now. Grid resiliency is not the problem—it’s planning.”

Many commercial vehicle users don’t have the confidence to even consider that planning.

A 2023 survey by Commercial Truck Trader found that 79% of “commercial truck shoppers would ‘never’ consider adding an electric vehicle to their fleet” because of range and battery life.

And a Fleet Advantage benchmarking survey released this fall similarly showed diminishing enthusiasm. Last year, two-thirds of respondents said they were “most interested in electric trucks”; this year, that number was one-third. Fuel cell electric trucks, which have longer ranges, improved from 15% to 38.5% in fleet interest over two years in the same survey.

The only way to build more confidence is more data. That will take time.

ROI and residual value

Mohr thinks electric trucks have a bright future ahead but also calls himself “the biggest pessimist in the EV business” due to trucking’s troubles rolling out emissions technology over a decade ago.

“Our industry has gone through its fair share of heartbreak,” he noted, citing questionable technology, high running costs, and bad residual values—or the money recouped after selling the truck.

Residual value is a big part of calculating total cost of ownership, and it’s imperative to have an idea of TCO prior to making an investment in new equipment. Residual value won’t be known for seven years, Mohr said.

One big question mark surrounds the battery depreciation. According to Volvo Energy, after seven or eight years, a lithium-ion battery loses 20 to 30% of its capacity. Diesel trucks will also lose fuel efficiency over time, but this type of loss on an electric truck, where range is only a few hundred miles, severely limits range and increases the amount of time a driver will have to stop and find a charger, plus the time it takes to charge. That further cuts into TCO. Battery tech is expected to improve, but that would make current BEVs’ value depreciate more down the line.

“Everyone talks about total cost of ownership, but without a residual value that they have any confidence in, the TCO doesn’t make any sense for a long time,” Mohr said.

Fleets appear to feel the same. In that previously cited Fleet Advantage survey, 90% of respondents said cost and calculating TCO were a concern. Of the major barriers to adoption, nearly half identified not having a “proper way of calculating costs involved” and not being “convinced there will be a decent ROI.”

Fleet Advantage does have a software tool to calculate a leased electric truck’s TCO called EVAN (Electric Vehicle Analytic Navigator). According to Fleet Advantage, EVAN uses factors such as the truck’s initial price, charging costs, incentives, maintenance costs per mile, and projects the sum a fleet will pay over six years, and compares that to a comparable diesel truck.

In one model using a Florida food delivery fleet’s data, a 2024 diesel truck cost $43,000 less over six years than an electric truck. The EV was 25% less in maintenance and repair and 45% better in fuel costs but more than double the diesel truck’s financing costs.

OEMs are indeed aware of the early-stage challenges and risks a fleet will have to take. Their solution is to push renting and leasing as options.

“We’re working to help franchises and our customers identify, apply for, and obtain grant funding to lower their capital investment as they transition to [EVs],” said Andrew Keane, PacLease director of franchise operations.

When leasing, a fleet will likely end up paying more in the long run but with fewer headaches.

Lingering issues

This is all just scratching the surface of major problems with electrifying too soon. Since EVs are equipped with heavy lithium-ion batteries, they weigh more than their conventional counterparts. This could put more stress on roadways and speed up the development of potholes.

The Indiana Department of Transportation (INDOT) designs pavements based on the current average daily truck traffic to last approximately 50 years, according to Natalie Garrett, INDOT strategic communications director.

“If heavier legal loads are approved through federal regulations,” Garrett explained, “then design standards for pavement and bridges would need to be updated to account for those heavier loads.” She added that unless standards are changed, CEVs will have to abide by the existing limits and find another route.

Many states rely on fuel taxes to repair potholes and crumbling roads. In Indiana, about 82% of the agency’s state revenue is derived from motor fuel taxes, which accounts for 61% of INDOT’s total revenue, with the remaining 39% being federal, Garrett said.

“INDOT is projecting a shortfall in the future due to EV adoption,” said Garrett, who added the agency is providing data to the state legislature to figure out a solution.

A vehicle-miles traveled (VMT) tax may be in order, but that itself comes with problems. According to Jana Jarvis, Oregon Trucking Association president and CEO, her state’s weight-mile tax has issues, among them tax evasion and the cost of collecting the taxes.

“I have a pretty good idea it’s well in excess of 20%,” Jarvis said. “The cost of a collection for a fuel tax is 0.5%, which means you have to raise the rates higher to get the same revenue and to support whatever it is you’re supporting.”

ATRI’s analysis of VMT concluded that evasion and noncompliance will exceed $7.87 billion annually, and collection costs would be 300 times higher than for the federal motor fuel tax.

“It’s going to cost 40 cents to collect $1 based on VMT compared to 3 cents now,” explained Paul Enos, CEO of the Nevada Trucking Association. “So where does that 37 cents go? It goes to Silicon Valley, it goes to banks—instead of going to our roads, instead of going to those things that we want the government to do in an efficient way. We’re now giving it to people who are taking this grift, and that isn’t going to benefit us as citizens.”

About the Author

John Hitch

Editor-in-chief, Fleet Maintenance

John Hitch is the award-winning editor-in-chief of Fleet Maintenance, where his mission is to provide maintenance leaders and technicians with the the latest information on tools, strategies, and best practices to keep their fleets' commercial vehicles moving.

He is based out of Cleveland, Ohio, and has worked in the B2B journalism space for more than a decade. Hitch was previously senior editor for FleetOwner and before that was technology editor for IndustryWeek and and managing editor of New Equipment Digest.

Hitch graduated from Kent State University and was editor of the student magazine The Burr in 2009.

The former sonar technician served honorably aboard the fast-attack submarine USS Oklahoma City (SSN-723), where he participated in counter-drug ops, an under-ice expedition, and other missions he's not allowed to talk about for several more decades.