Emissions critical: How to solve the aftertreatment diagnostics dilemma

Aftertreatment systems have improved by leaps and bounds since 2010 when diesel particulate filters and selective catalytic reduction became standard on heavy-duty diesel trucks. These systems capture more harmful emissions and are more reliable, while fleets better understand what it takes to keep them performing properly.

For more on emissions system maintenance:

“We have learned a lot about monitoring aftertreatment systems and optimizing preventive maintenance practices, and understand that using quality replacement parts, scheduling, and managing idle hours are critical,” explained Joe Puff, VP of truck technology and maintenance at NationaLease.

Still, Puff explained that training techs and drivers remains “the biggest aftertreatment challenge today.”

That’s because as these systems evolve, technicians need to stay up-to-date on all their service and component changes, as well as new issues that can spring up while staying proficient on previous versions. Even experienced troubleshooters can’t hit all of these moving targets.

It’s a reason why on diagnostic solutions provider Noregon’s 2025 “Unpacking the Commercial Vehicle Diagnostics Industry” report, 38% of the vetted respondents pointed to the aftertreatment system as the most challenging component to work on, just 2% behind the top answer, vehicle electronics, which stretch across the entire truck.

But for uptime to stay consistent, fleets must rise to meet the emissions challenges.

“Knowing how to properly diagnose and repair these systems is critical given how easily they can reduce an engine’s power output or shut it down entirely,” explained Jason Hedman, product manager at Noregon.

TOP 5 SHOP CHALLENGES

- 61%: Hiring technicians

- 44%: Accurate/effective troubleshooting/diagnostics

- 39%: Reducing dwell time of vehicles awaiting service/repair

- 32%: Training

- 26%: Inefficiencies in repairs

TOP 5 FLEET CHALLENGES

- 54%: Accurate/effective troubleshooting/diagnostics

- 48%: Hiring technicians

- 42%: Training

- 39%: Reducing dwell time of vehicles awaiting service/repair

- 28%: Managing repairs

Source: Noregon Research

For example, at any time, a deterioration in the emission system’s performance may cause a truck to go into derate. This forces the driver to stop and manually force the emissions system to complete a regeneration cycle to burn off soot collected in the diesel particulate filter. Unless the derate was due to the engine not getting up to the correct temperature due to an on-road factor, such as excessive idling or an ill-timed traffic jam, there’s a problem only a proper diagnosis can sus out.

Finding out what the root cause is requires both properly trained techs and the right tools that can detect and repair issues on modern emissions systems. And even more changes are on the way to meet 2027 NOx standards. They also have to keep up with older trucks too, as Noregon’s report noted that 75% of heavy-duty trucks are already eight years old or more. Without the training, critical thinking skills, and tools, no fleet running diesel trucks will get very far. That’s why we caught up with several diagnostic experts to explain why all three are vital.

No train, no gain

The most glaring issue is keeping shop techs up to speed on the evolving systems. Longer diagnostic time leads to a backlog of work in the shop.

Sandeep Kar, chief strategy officer at Noregon, attributes high shop dwell times for trucks to a generational skills gap and lack of proper troubleshooting devices. “Older technicians are having a hard time figuring out what these electronics are really spitting out in terms of information and insights, and younger technicians don’t have the right tools,” he told Fleet Maintenance.

But where should shops start? Diagnostic efficiency is likely a good place. Hedman explained that techs sometimes have a wasteful approach to troubleshooting and repair.

“A common mistake we see with aftertreatment system maintenance is technicians rushing to force a regen when they see an aftertreatment fault, rather than performing a proper diagnosis,” he said. “Unfortunately, an unnecessary regen can take a bit of time, burn fuel, and render the system too hot to work on for a while, so it leads to inefficiencies and lost profits in the shop.”

Not having enough training resources available seems to be another source of inefficient troubleshooting.

“One of the main challenges is the difficulty in accessing resources that make it easier to understand and resolve both mechanical and electronic issues, which are often very complex,” noted Jorge Verdejo, sales director at Cojali USA. “These resources go beyond tools—they include training or even online expert services that technicians can consult when needed.”

Cojali offers various in-person and online training through Jaltest University. Courses range from the scan tool basics to more direct training on DEF systems and NOx sensors.

Diagnostic sidekicks

Most diagnsotics can be performed by scan tools that connect to the vehicle, but don’t forget about the other helpful devices a tech can use to troubleshoot issues.

Sam Lord, director of maintenance and telematics at Kirk NationaLease, said laser thermometers and thermal imagers “not only provide quicker identification and verification of issues, but also provide the technician with a better understanding of the operation of these modern systems.”

And Luke Powell explained borescopes can also be useful, especially when locating DEF doser problems. When the doser is stuck open, excess DEF won’t react with the NOx generated by the engine, but instead will crystallize. Powell said he will unfasten the three bolts to remove the doser and slide the borescope’s camera end into the system to confirm if crystallization occured. Crystals may also appear if the urea is of poor quality, so fleets should also test the DEF when crystals are present to improve the system’s NOx reduction.

More online and in-person training with vendors is the long-term solution, but that takes time. For immediate training triage, the OEMs offer expert help through uptime call centers. On the vendor side, Noregon offers Technicians as a Service. This connects technicians stuck on a difficult job with remote experts who can walk them through that specific task while providing some teaching tips so they are more prepared for the next one.

“This reduces the need for less experienced mechanics to pull away a coworker from another job while ensuring the vehicle doesn’t face additional unplanned downtime,” Hedman said.

Emphasizing the root cause

But phoning a friend can’t be the default solution. For techs to advance as diagnosticians, they need to figure things out for themselves. To do that, they need to know how pumps, wires, and valves all interact with one another. But that doesn’t come easy.

“The biggest challenge is understanding how it all works,” offered Luke Powell, a technician at Fleet Pride in Lancaster, Pennsylvania.

Without figuring this aspect out, a technician will never see the full picture, and thus never achieve their full troubleshooting potential.

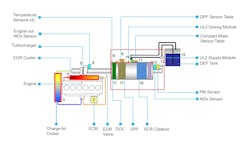

“Diagnosis is more about understanding the system; it’s not just one box or component, it’s multiple components from the turbo and EGR valve to the seventh injector and the DEF doser for the SCR system,” explained Michael DeMarinis, training and development manager at Boss Truck Shops.

DeMarinis noted all these systems are interconnected, requiring a tech to identify all the issues so they can properly perform a root-cause analysis.

“If you get a NOx sensor code, you can’t just replace that sensor,” he said. “You must first diagnose the problem that caused the high NOx. Just replacing a sensor when it’s only providing an indication of trouble ends up being frustrating for both the technician and customer.”

A fleet that does this not only spends hundreds on the sensor but must also factor in the downtime and labor costs. And the worst part is that the problem, hiding somewhere upstream undiagnosed, has not been resolved, either.

Powell noted such problems can range all the way from an exhaust system leak that deprives the DOC and DPF of necessary exhaust heat to a failed air dryer desiccant filter. Debris from that filter can clog the air supply, which enables the fuel doser (or seventh injector) to work, thus interfering with the doser’s job of keeping the DOC and DPF hot.

These two interlinked components must remain hot enough to burn off hydrocarbons, and especially particulate that’s trapped by the DPF until it combusts. Powell said another root cause may be an EGR valve not closing properly, which can result in excessive soot clogging the DPF.

Intimately knowing the system, combined with experience, helps techs like Powell dig down to the root cause more quickly.

It also involves upgrading the most valuable diagnostic tool at your disposal: your tech’s brain. The ability to logically trace the symptoms to the root cause takes a specific mindset. Two methodologies, the fishbone diagram and the 5 whys, can help a tech organize their thoughts—and possible causes and effects—more clearly to systematically discern the root cause. To best apply these strategies for aftertreatment or any kind of troubleshooting, take a look at Technology & Maintenance Council Recommended Practice 551: Root Cause Analysis, which was approved this year.

About the Author

John Baxter

John Baxter is a freelance truck journalist and serves as the technical director of Advance Diesel Concepts, a small venture that is developing a stratified-charge-compression ignition combustion system that will shortly be tested at Argonne National Laboratory. He is a full member of SAE International and a member of the Truck Writers of North America (TWNA) and serves on its Technical Achievement Award committee. Over his long career, he has been employed by a number of the major truck industry publications.