Range electric trailer powers 4-mpg improvement, MVTS study finds

After testing the Range Energy RA-01 53-ft. electric-powered trailer, Mesilla Valley Transportation Solutions (MVTS) has found the system has a signifigant impact on fuel economy. According to a report on the results, a test tractor mated to a loaded Range RA-01 electric trailer had around a 36% fuel economy versus a like tractor coupled to a 53-ft. Hyundai dry van trailer. Over three test scenarios, this amounted to nearly a 4-mpg improvement.

Stop/Go, Urban Test: 3.25 mpg

Flat highway: 4.69 mpg

Entire test route: 3.82 mpg

"Results from MVTS’ certified testing paired with our fuel and emissions savings testing prove Range’s ability to optimize drive behavior and efficiency, quantifying significant fuel savings and electric energy consumed,” said Ali Javidan, CEO and founder of Range Energy, which was created in 2021. “With these test results, we can provide accurate predictions of efficiency and safety improvements and emissions reductions, accelerating the decarbonization of commercial trucking.”

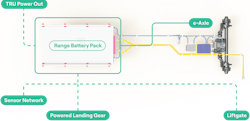

The Range Energy electric trailer system uses an electrically powered drive axle, thus reducing drag on the tractor and reducing the amount of fuel consumed. The platform includes

The system also puts the trailer in a constant state of ‘pull,’ meaning that driving the tractor feels as though the load is lighter. The electric trailer also includes a battery pack to power the electric axle, which was fully charged before testing took place. MVTS noted that this improvement in fuel economy does not constitute ‘free’ energy due to the need to charge the battery, but does expect that electric charging is more environmentally clean and cost-effective than a diesel-powered alternative.

Read more: How integrated powertrains, engine controls impact fuel efficiency

Testing took place in El Paso, Texas, on a 25.5-mile route with a mix of urban and highway conditions. MVTS used International LT 625 6X4 sleeper cab tractors with Cummins X15 engines. The payload for each was 20,000 lbs. The electric trailer and tractor had a GVW of roughly 59,000 lbs. and travelled at 60 mph at its top speed. The control model with the Hyundai trailer weighed in at 55,000 lbs. In total, MVTS ran 16 test loops, driving a total of 408 miles.

Ten different types of sensors were used to gather data, including diesel fuel flow meters, temperature sensors, and wind and air pressure sensors. The diesel fuel economy improvement was calculated over the average of the 25.5-mile loop, with certain circumstances yielding different results. For instance, stop-and-go portions of the loop yielded 36.9% savings (3.25 mpg) while flat, steady-speed portions of the loop yielded 35.3% improvements (4.69 mpg). While actual fleet fuel economy savings depend on its duty cycle, MVTS’ testing yielded an improvement percentage of 35.3-36.9% (4.69-3.82 mpg).

Finally, while the company did not test how the trailer could improve the range of an electric tractor, it did say the expected fuel savings could increase a tractor’s range for both electric and fuel-powered vehicles.

For all the details, check out the full MVTS report.