First look at DTNA EPA27 engine: Detroit meets NOx goals and exceeds expectations

Key Highlights

- Detroit’s Gen 6 engines are designed to meet EPA’s 2027 NOx standards

- The engines feature a pre-SCR module, improved turbochargers, and new power ratings to enhance performance and efficiency across vocational and linehaul markets.

- Familiar technology and maintenance intervals from Gen 5 ensure minimal disruption for technicians and fleet operations.

- Advanced heat management and combustion improvements contribute to increased durability and reduced downtime, supporting long-term fleet reliability.

- The engines offer a potential 3% fuel efficiency increase, with no significant price hikes, providing value amid ongoing freight market challenges.

DETROIT—With about 10 months until the EPA’s low-NOx rule for heavy-duty engines takes effect, Daimler Truck North America’s engine brand, Detroit, has revealed major details regarding its EPA27-compliant engines: the Gen 6 DD13, DD15, and DD16.

These engines will fit the Class 8 on-highway market leader Freightliner Cascadia, as well as the vocational complement, Western Star 47X and 49X. The DD13 and 15 will be available next January, while the DD16 arrives a year later.

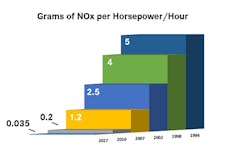

Fleet Maintenance was among the media invited to the reveal at the Detroit Manufacturing Plant and subsequent plant tour. Aside from the obvious—that the engines will be compliant with EPA’s 2027 rule, which lowers the federal NOx standard 82.5% from 0.20 to 0.035 g/bhp-hr—the bigger takeaway is that the Gen 6 lineup was engineered to manage heat transfer more efficiently and improve power and uptime without adding significant complexity for fleets or technicians.

That means maintenance intervals and most part numbers also carry over from the Gen 5 released in 2021.

“It's really familiar technology,” noted Greg Brazuinas, Detroit head of powertrain engineering for North America, adding that everything from the sensor suite and controls to diesel particulate filter remains the same.

He should know, having worked on the platform since 2003, when it was a blank sheet being developed for the 2007/2010 federal emissions standards that ultimately set the 0.20 g/bhp-hr NOx limit for heavy-duty engines.

When the EPA announced this round of NOx cuts at the end of 2022, many in the industry wondered if the OEMs had enough time to meet the new goals. The reveal was more of a victory lap for DTNA’s engineers, who are highly confident they exceeded expectations.

“We've made evolutionary steps to improve efficiency, improve performance, and improve reliability—all things that our customers really demand.” Brazuinas asserted.

That confidence is based on state-of-the-art testing at the plant and 8 million real road miles.

“We've definitely put this thing through the wringer, and we've been developing this product for almost seven years,” he said. “We started even before we knew the final emission regulations.” This included multiple winter trials in -40 degrees Fahrenheit and summer tests up to 130 degrees Fahrenheit, as well as idle testing.

What’s new with Detroit Gen 6 heavy-duty engine?

Detroit’s engineers tackled this challenge by adding a pre-SCR (Selective Catalytic Reduction) module on top of the 1-box to dose diesel exhaust fluid upstream of the main aftertreatment system.

With this comes an extra NOx sensor, which is not much different than the previous generation. The pre-SCR does add a lot of flexibility based on environment, though.

“In a cold start environment where the aftertreatment system hasn't quite come up to temperature yet, we can warm up that pre-SCR chamber more quickly, so maybe the primary amount of NOx conversion actually happens in that pre-SCR chamber,” explained Steven Collins.

While Cummins added a 48-v heater to their new SCR system, Collins said Detroit achieves the same effect using exhaust heat. “At the very simplest and basic, we're utilizing a slightly smaller box and putting it closer to the heat source, so it heats up more quickly,” he explained.

On the performance side, Detroit added three new power ratings. The DD13 now has a 505 HP/1,750 ft.-lbs. torque rating, which was done for vocational customers not wanting to go up to 1,850 ft.-lbs. The DD15 now has a 425 HP and 455 HP, both at 1,900 ft.-lbs. of torque, allowing linehaul drivers to further downspeed for added efficiencies.

“Super-fast axle ratios, like a [2.05:1 rear axle ratio] paired with the direct drive transmission, spin the engine slower and harder, and accomplish additional fuel efficiency savings, while keeping the same seat feel for the driver,” Collins said.

The Gen 6 turbocharger on all engine ratings now uses a ball-bearing design to spool faster, delivering air flow on demand more quickly. The new wastegate has more precise controls as well, boosting performance at high altitudes.

With the help of a thermal control valve, the system also gets hotter faster and should mitigate the need for drivers to perform a manual “parked regen,” according to DTNA.

Speaking of emission-related downtime, Brazuinas noted DTNA has fulfilled EPA’s 2025 request to update DEF control software to ease derates and limp mode for the Gen 5, releasing the service calibrations and fuel maps in January. The Gen 6 will have those inducement changes baked in, he said.

Improvements to combustion and air controls on the engine side also contribute to heat and power management while enhancing overall performance. These include an asymmetric intake port, redesigned fuel injectors, Miller timing on the camshaft to reduce the work of compression and increase the compression ratio, and a wastegate actuator to aid truck efficiency at high altitudes.

The EPA also demanded that engine OEMs extend useful life and warranty periods—though this part of the rule is subject to change—so the Gen 6 engines were designed not only to be more efficient, but more robust as well.

For example, the high-pressure fuel pump was replaced by an oil-lubricated fuel pump. Lubricating with engine oil reduces sensitivity to varying fuel quality, improving long-term durability, particularly as fleets deal with inconsistent diesel blends.

The updated system now delivers fuel rail pressures up to 2,500 bar, improving atomization and combustion efficiency. In the previous generation, lower rail pressure was achieved centrally and additional pressure amplification occurred at the injector. The redesigned method simplifies injection control and enhances precision.

Barring a few other tweaks, DTNA asserts the engine and aftertreatment systems are basically the same in terms of operation and maintenance.

Popping the hood on other changes

Even with the pre-SCR protruding from the top of the 1-box, the system still fits neatly under the hood of all relevant models, requiring no back-of-cab changes for vocational customers.

“There are new part numbers for fuel filters,” added Steven Collins, Detroit Director of Field Sales Engineering, “but in terms of maintenance intervals that technicians would be most commonly looking at, those are all the same. From a technician standpoint, obviously there's training anytime there are new part numbers or anything like that, but overall, [the new engine has] lots of commonality and familiarity.”

To improve efficiency and reliability, while keeping everything similar enough to not disrupt fleet uptime, the engine had to optimize combustion and air flow, while reducing friction and pressure.

“If we reduce friction, we can get more of the power that the engine produces to the wheel ends, with less parasitic losses,” Collins said.

“The aftertreatment system really is the star and show, but that simple, low complexity design wouldn't be possible if we didn't already have an extremely efficient engine upstream,” he said.

The engine now uses an electronically controlled variable-displacement oil pump, which reduces parasitic losses and improves overall efficiency. Lower frictional losses allow more of the engine’s produced power to reach the driveline.

The oil separator, which helps reduce crank case emissions, is now driven electronically versus hydraulically.

“This gives us more control and better separation efficiency at low loads, low speeds, and at idle,” Collins said. “And really, by removing the oil-driven side, we can combine that with the variable speed oil pump to reduce overall oil flow and demand on the pump.”

Fuel quality is also improved with new fuel filters. Previously, the system heated fuel returning from the rail. Now a heating element in the module does that, which customers in cold climates should notice will prevent diesel gelling and buildup, according to Collins.

Value for customers

The EPA27 platform “is not just an emissions change,” added David Carson, DTNA’s SVP of sales and marketing. “It goes beyond that, and we are bringing value to the customers.”

Some of that value may be found at the pump, as the new platform can provide a 3% fuel-efficiency increase in certain linehaul situations, he said.

Carson also added the EPA27 engine won’t lead to a “massive price increase,” as some in the industry had previously estimated. Carson did not reveal the new number, but the most common estimate until recently has been $20,000 to $30,000.

This should provide some relief to fleets still struggling with what Carson called “the longest freight recession we've ever seen in the industry.”

This has led to fleets keeping longer than usual. Noregon Research estimated about three-fourths of trucks operating in the U.S. are at least eight years old. In addition, the expected prebuy has also not materialized as customers more closely monitor CAPEX based on freight capacity. That’s not ideal for DTNA or the other OEMs that have sunk several years and untold riches into the greener engines.

“We did see at the end of last year, moving into the beginning of this year, pretty healthy order demand, which is encouraging,” Carson said. “We're not at the point where we would say that that is a complete recovery, or that it’s necessarily sustainable moving forward.”

But trucks age out, and at some point, fleets will need to buy new trucks. And if they choose Freightliner, which is still the market leader, at least this regulation change looks to be relatively painless.

About the Author

John Hitch

Editor-in-chief, Fleet Maintenance

John Hitch is the award-winning editor-in-chief of Fleet Maintenance, where his mission is to provide maintenance leaders and technicians with the the latest information on tools, strategies, and best practices to keep their fleets' commercial vehicles moving.

He is based out of Cleveland, Ohio, and has worked in the B2B journalism space for more than a decade. Hitch was previously senior editor for FleetOwner and before that was technology editor for IndustryWeek and and managing editor of New Equipment Digest.

Hitch graduated from Kent State University and was editor of the student magazine The Burr in 2009.

The former sonar technician served honorably aboard the fast-attack submarine USS Oklahoma City (SSN-723), where he participated in counter-drug ops, an under-ice expedition, and other missions he's not allowed to talk about for several more decades.