How oil analysis data refines your PM strategy

In the world of fleet maintenance, data has become one of the most valuable tools in driving both performance and profitability. One of the most impactful—but often underutilized—sources of that data is oil analysis. As a lubrication expert, I’ve seen firsth and how diagnostic oil data transforms fleet operations by replacing outdated mileage-based oil change intervals with condition-based strategies rooted in real engine health.

The result? Fleets gain better control over maintenance planning, reduce unnecessary service costs, and avoid catastrophic failures—all by listening to what the oil is telling us.

From mileage-based to condition-based oil intervals

Engine oil is much like the blood in our bodies—when tested, it reveals vital information about overall health. In engines, that means insights into wear, contamination, and the overall health of the system.

For years, fleets have relied on fixed oil schedules, the good old “every X miles” approach. While this approach is simple, it doesn't account for real-world variables like load weight, driving conditions and habits, fuel quality, or engine type. Two trucks might travel the same distance, and yet their oil conditions can greatly differ based on how and where they operate.

That’s where oil analysis comes in. By shifting to a condition-based interval approach, oil changes are guided by actual oil health—not just mileage. This allows fleets to safely extend oil intervals, reduce unnecessary maintenance (scheduling smarter, not harder), and make more informed and cost-effective decisions.

Extending drain intervals

Of all the benefits oil analysis brings to fleets, the ability to safely extend drain intervals (ODIs) has the biggest operational impact. Understanding the true condition of the oil allows teams to determine the optimum drain interval—one that maximizes oil life without risking engine damage. This directly translates to cost saving by reducing oil change frequency, labor time, and downtime. And when every mile matters, extending ODIs is a clear win.

Fleet maintenance benefits

From a fleet perspective, the shift to oil diagnostic data brings multiple benefits:

- Reduced downtime

- Labor savings

- Trend-based adjustments

- Improved cost efficiency across the fleet.

Sampling best practices for new users

New to oil diagnostics? No problem. Getting started with oil analysis is simpler than many believe. Here’s how:

- Register all tracked equipment with your lab’s system.

- Submit a sample of unused oil to establish baseline reference values.

- Begin sampling at regular intervals, compare results, and make data-informed decisions.

Just a few samples can often reveal early issues or confirm oil quality, tuning a skeptic into a true believer.

Here’s how I recommend fleets approach oil sampling and diagnostics:

- Start with OEM or Oil Supplier Guidelines as your baseline.

- For your initial sampling, always take a sample of new oil to establish a clean reference point. Follow that with a sample at the normal drain interval.

- Then adjust your ODIs based on trends. If results are stable, extend oil change intervals by 5–10% and keep monitoring. If results show issues (like metal spikes or contamination), shorten the next interval until the issue is resolved.

- Many fleets test every oil change. For high-value or high-mileage assets, a mid-interval sample can provide early warnings.

Common problems in oil data

While oil analysis reports can be essential to a smart maintenance strategy, fleets and technicians should watch for the following warning signs in oil analysis reports:

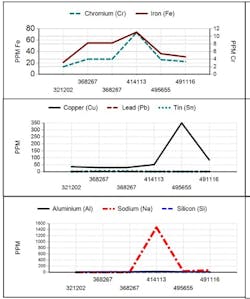

- Coolant intrusion: Sodium, potassium, and water content suggest a possible head gasket or cooler leak.

- Fuel dilution: A drop in viscosity may mean unburned fuel is entering the crankcase.

- High soot/oxidation: Oil thickening points to potential sludge or deposit formation.

- Metal spikes:

- Iron + Chromium = piston ring or cylinder wear

- Copper = bearing or cooler issues

- Aluminum + Iron = piston scuffing

These issues, when caught early, can prevent serious and costly engine damage.

Unlocking deeper insights with modern predictive tools

While basic oil reports are valuable, modern fluid condition monitoring services are being used for predictive and preventative equipment maintenance. State-of-the-art tools, like CITGO LubeAlert, are used for predictive and preventative equipment maintenance. These fluid condition monitoring services are used for predictive and preventative equipment maintenance and help elevate data into an integrated maintenance solution by:

- Detecting early signs of wear, fuel dilution, or coolant leaks

- Tracking trends to extend drain intervals or flag issues sooner

- Prioritizing repairs with clear severity ratings

- Automating work orders via system integration

- Measuring ROI through reduced downtime and oil use

Data-driven lubrication is in

There is no way around it: Oil diagnostic data has become an essential part of modern fleet management. It offers fleets more than just a snapshot of engine health – it provides a pathway to safer, smarter and more sustainable maintenance. From extending oil drain intervals to catching wear before it becomes failure, oil analysis empowers fleets to make proactive decisions grounded on real data.

Whether you're just starting your oil analysis journey or looking to get more value from your program, just let the oil do the talking—and make sure you listen closely.

About the Author

Brandon Thompson

Brandon Thompson is the product marketing manager, Lubricants at CITGO Petroleum Corporation. With 19 years of experience across lab operations, product development, and compliance, he is passionate about driving success for CITGO's brands while leveraging his deep expertise in the lubricants industry. He holds a Bachelor of Science in Chemistry from Xavier University of Louisiana and a master’s in public health from A.T. Still University.