How often does your shop have to turn away business because you don’t have the right tools or equipment? This likely has happened with various makes’ advanced driver assistance systems, or other new or niche components, because it’s often too costly to stock such tools and equipment that don’t have a promising ROI. That said, if you don’t have adequate lifts to service customer vehicles in your area, you may be missing out on jobs that will not only provide a nice return on the lift, but create plenty of return customers as well.

For instance, if your shop typically services light-duty and consumer vehicles, but you have the space and labor to accommodate medium-duty as well, maybe your next lift should have a 14,000-lb. capacity. This will allow your shop to accommodate more of the growing last mile segment, which, due to the start/stop nature of the route, requires more tire and brake maintenance.

Read more: ALI's Digital Lifting Points Guide aims to prevent accidentsThere is one big caveat: Lifts should typically last at least a few decades, and in the next 10 years electric vehicles, which are heavier than fossil-fuel-powered models, will be more prevalent in both the consumer and commercial space. This means you should not just spec for the business you have today, but what you want tomorrow as well.

To help you do that, here are some updates from several of the leading lift manufacturers.

What’s new?

Jason Matthews, product manager, automotive lifts, for Rotary Lifts/VSG, says they have some new alignment lifts for shops that are tighter on bay space. “The XA12 is an alignment lift that’s specifically designed for small bays. Our XA14 is a large scissor alignment lift. It can accommodate a wide range of vehicles, but not everybody has the space for a large lift like that. The XA12 is a perfect solution for an owner who has a small bay but still needs to do alignments on cars and trucks.”

Matthews says that Rotary’s model numbers typically correspond to the capacity. “The [XA12] is a 12,000-lb. capacity scissor lift. It works really well with cars and other unibody vehicles, all the way up to smaller trucks.”

The XA12 can handle trucks up to F-250 and F-350s (unloaded), according to Matthews. But due to the big feature of this lift, even though he says it has the largest four-wheel alignment wheelbase range in its class, there are some limitations based on the size of the bay area. “The maximum wheelbase for two-wheel alignments is 166". So, if you have a truck that had a longer wheelbase than that, then I mean, that would be the only concern. But the really long wheelbase trucks are the exception, not the rule. The vast majority of vehicles are going to fit on [the XA12].”

Matthews says that if your shop works on a lot of vehicles with longer wheelbases, then it would make more sense to move up to the larger XA14, 14,000-lb scissor lift that has much longer runways. But you need to have a lot more bay space for these lifts. The small lift still takes up a 13' by 28' bay. And that includes using Rotary’s aligners, which are more compact.

“What’s unique about [our aligners] is that they don’t have the towers with the cameras that go in front of the lift,” Matthews explains. “Our cameras actually mount to the side. So you don’t have to have that extra space in front of the lifts to do alignments. Our 1090 and 1065 aligners help save space and enable someone that doesn’t have a lot of space or a small bay to be still able to perform alignments and earn revenue on these jobs.”

Matthews acknowledges that lift companies have become more safety conscious with all of the testing and inspections that are part of the industry today. He says that Rotary is one of the founding members of ALI, so they are very much in favor of these certifications, but they only test the strength or capacity of the lift. What is not covered in the certification process is the durability of the lift.

Read more: A closer look at lift inspections“Longevity and low cost of ownership are really important,” says Matthews. “Those are all things the company is passionate about, and we make sure that technicians and shops are able to use our lifts and earn money with them for a very long time.”

Durability testing is one of the most important aspects of Rotary’s lifts besides its safety certification, Matthews explains. “We cycle our lifts 20,000 times with full load. It’s akin to what an automotive manufacturer does when they’re designing a vehicle. There’s a lot of strength testing, which is what goes into that Gold Label testing. With durability testing, that’s the determinant of longevity that the lift is going to last for a long time.”

With over 150 new electric vehicles that are out now or will be coming out in the next two to three years, shops will need to start preparing for this new technology that many techs have not seen before, and it will require some new equipment to handle them properly.

“There will be a lot of new things that a technician will have to worry about,” Matthews says. “Shops will have to make sure they have the right equipment. The lift, for example, must be able to reach in and contact the specific pickup points that are right next to the battery underneath the vehicle.”

According to Brian Spikes, vice president and general manager of Challenger Lifts, they launched several products for new automotive technologies (i.e., EVs) at the 2022 SEMA Show last November. “Our EnviroLift wide series in-ground lift offers an industry-leading distance between cylinders, providing more room for battery removal and the width required to service today’s wide-bodied or exotic vehicles.”

Spikes says they have two new models of battery lifting tables designed to safely remove a battery of up to 3,300 lbs. from underneath a lifted electric vehicle (EV). And Challenger also introduced an adjustable 12K two-post lift, which can be installed in three widths and heights - a feature available on their 10K, 16K, and 20K models.

“All 12K through 20K offerings serve the heavy-duty market,” says Spikes. “We also launched medium-duty 5K mobile columns. These will allow shops with limited space to have the flexibility of a mobile column system in a more compact form and at a lower price point.”

Finally, Spikes says Challenger added a new feature to their popular four-post lifts: hot-dipped, galvanized runways. “These rust-resistant runways are perfect for shop environments that encounter melting snow and ice and the road salt that is usually associated with those conditions.”

Lifting has evolved with the changing needs of vehicles, notes Spikes.

“20 to 30 years ago, your grandfather’s Cadillac, weighing 4,500 lbs., was the largest vehicle being lifted. Today, we lift 25’ long four-door dually trucks that weigh 12,000 lbs. We also saw the introduction of the unibody vehicle, where there was no frame on which to lift.

“To accommodate those vehicles, we went from a two-stage arm to a three-stage arm, allowing more length and retraction to hit frames and pinch welds. We also offer wider lift options on all commercial two-post and in-ground lifts with three-stage arms to add more flexibility in reaching the lift points." This trend continues today with the new EV vehicles, requiring changes to lifts to accommodate the addition and placement of the batteries.

In-ground lifts were once the only equipment available for lifting. They were a great product back in the day and lasted for years, according to Spikes. However, the issue, discovered later in their life cycle, was that they were not environmentally friendly. "These lifts were fully hydraulic and filled with numerous gallons of oil. If they leaked, oil went into the ground.”

As environmental awareness evolved, Spike says Challenger and the industry have grown to offer environmentally friendly in-ground options. Their 10K, 12K, and 15K in-ground lifts are now low oil, high-pressure, and encased in an environmentally-friendly cassette, so if there are any leaks, the oil cannot reach the soil. The change to a cassette also allows the lift to be serviced without digging the lift out of the ground. In fact, Challenger is now building their new, wide in-grounds similarly.

Two-posts ‘reimagined’

“Two-post models are the most popular car lifts in the world,” says Jeff Kritzer, BendPak president and CEO. “But just because something has been around a long time doesn’t mean it can’t be improved.”

Subsequently, BendPak's AP Series lifts are the company’s most customizable, versatile two-post lifts ever. The new lifts can fit most bays with either a wide or narrow configuration, and their redesigned swing arms enable both symmetric and asymmetric lifting from a single lift. Each AP Series lift comes with a standard adapter package for compatibility with a wide range of vehicles in one of three 10,000-lb. capacity models.

The standard 10AP has 73” of lifting height and an overhead beam height of 145” for shops with lower ceiling clearances. The 10AP-168 has the same 73” of lifting height plus a crossbar that’s positioned two feet higher to accommodate high-roof cargo vans. The 10APX is a high-rise model — great for taller technicians — offering 79.5” of lifting height with a 157” top beam. The 10APX-181 maintains 79.5” of lifting height and increases the top beam height to 181”.

“We put more than 50 years of experience into reimagining the two-post lift to make it more efficient, safer, and easier to use,” Kritzer adds. “We’re really proud of the results and hope our customers love it, too.”

Heavy-Duty Alignment Racks

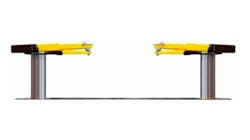

Pete Liebetreu, vice president of marketing for Hunter Engineering, says they introduced two new lift options recently. “We have a large 35,000 lb. four-post lift that is already optimized for alignment. Up until the L494HD, there were no purpose-built racks for wheel alignment. There were some build-to-order variations, but nobody had an off-the-shelf solution until now. We also have pit variations of the same runway set for those who’d like to go that route.”

Liebetreu also notes their new slip plates for lighter-duty vehicles are completely unique to Hunter. “Most heavy-duty shops are not strictly heavy duty. They are typically commercial shops that likely have fleet vehicles with independent rear suspensions. So we have wide (30”) runways. This seems like something simple, but it really adds to drive-on ease and safety that is not well represented in the heavy-duty world today. The galvanized runway surfaces also add to the longevity of this equipment in the harshest environments.”

Mobile Column Lifts

Mobile lifts are certainly an option for shops that may not have the space or ability to install in-ground lifts. But lift experts say shops must be sure the concrete is level and able to hold the weight of the vehicle they are lifting. One tool that can help is Mohawk’s slope indicator tool. This tool works with AC and DC mobile column lifts. Since these lifts can be moved and placed anywhere in or outside of the shop, Mohawk has designed this tool with technician safety in mind. Simply place the indicator on the mobile column, and it will indicate the floor slope in degrees. Mohawk’s mobile columns can be used safely for up to three degrees of floor slope. The slope indicator ensures the safety of the lift, vehicle, and, most importantly, the technicians from a potentially unsafe lifting situation.

In-Ground Lifts

Oftentimes, lifting points guidance from the OEMs come from light-duty manufacturers, who are a lot more proactive in getting those out, according to Carl Boyer, Midwest regional sales manager, Stertil-Koni.

Boyer says that many of the commercial vehicles that shops work on today are using a modified chassis that the manufacturer doesn’t typically know how it will be up-fitted. “Some people may take the same chassis, and one will be made into a crane body and another into a service truck. At that point, I think one of the more important things on the commercial truck side is the weight differentials front to back.

“Some techs may look at a lift and say, ‘my truck doesn’t weigh 16,000 lbs.,’ but the problem is the way it is loaded. They could have 10,000 lbs. in the back and 6,000 lbs. up front. That’s not really a safe lifting application. So, it’s a little bit different on our side, perhaps, than it would be on the light-duty side.”

Boyer explains that heavy-duty repair shops have a lot of options when it comes to purchasing a new lift. It really depends on factors such as budget, space, type of facility, and even the groundwater level for those looking at in-ground lifts.

“I think in a perfect world, everybody would probably have an axle-engaging in-ground lift,” says Boyer. “But some facilities are rented or leased, and they can’t put things in the ground or permanently mount them to the floor. Other issues are going to be budgetary. There’s really no distinct disadvantages to an in-ground lift, with the exception of cost and modifying the floor, where you have to cut into the floor if you don’t already have an existing lift that you’re replacing.”

Boyer notes there are a lot of compromises with whether it is better for a certain shop to go with an above-ground lift or perhaps a mobile column lift. “They all have trade-offs. With mobile column lifts, you have two steps - an additional step to remove wheels because you’re picking them up from the wheels. You have to pick the vehicle up, set a jack stand, and use a high lift wheel dolly to remove a tire and wheel before you can do brake work, for example.”

But a mobile column lift also costs less, according to Boyer. “It’s going to cost half or a third of what it costs to put in an in-ground lift. That’s where customers have to start making a trade-off. How much am I willing to give up from a convenience standpoint or a throughput standpoint vs. the money you have to spend on a lift?”

Tim Kerr, engineering sales support manager for Stertil-Koni, says shops that opt for a mobile column lift over an in-ground lift have more things to worry about. For example, he says you need to think about if the floor is level and whether the rebar structure in the concrete is sufficient enough to lift one of these vehicles.

Kerr explains that there are a lot more steps involved in doing brake work, tire work, and hub work on a mobile column lift. “Any time you add additional steps, you’re just adding the possibility for human error. So with an in-ground lift, obviously, there’s an added cost, and it’s more complicated than mobile columns, but you eliminate a lot of those additional steps. And each one of those steps has the element of human error that can be involved.”

One thing is for certain; the industry is changing along with the new vehicle technologies. Shops in the market for a new lift must be prepared to handle this new fleet of vehicles, whether it is a gas, diesel, EV, or commercial truck.