Almost half of fleet managers can't schedule maintenance, Teletrac report says

Key Highlights

- Fleets and equipment companies continue to face challenges surrounding maintenance scheduling and expenses

- Technology can and is filling the gap, particularly with GPS tracking and data analytics

According to a report by telematics provider Teletrac Navman, almost half of the equipment managers surveyed admitted to struggles with maintenance scheduling, which has a neagtive impact on project costs.

The report, Mobilizing the Future of Fleets Report: 2025 Equipment Management Edition, also found a third of asset managers don't know where up to 25% of their fleet is at any one time, raising both costs and inefficiency.

For more on from Teletrac Navman:

“Whether it’s the high cost of repairs, difficulties in maintaining regular service schedules, or simply the challenge of locating equipment on-site, the impact on total cost of ownership is clear, so much so that the findings indicate that these issues are directly affecting their ability to control costs,” said Alain Samaha, chief executive officer, Teletrac Navman.

The report surveyed 736 equipment operator companies across the U.S., U.K., Australia, and New Zealand. For these organizations, 47% struggled with maintenance scheduling, while 45% considered maintenance expenses to be a challenge. Respondents also highlighted the growing complexity and expense of routine maintenance, especially due to parts shortages, labor, and timing.

All of this adds on to the root cause of fleets' inability to find and maintain trucks, that "many operators are still working reactively rather than proactively,” the report suggested. And this is despite nearly all respondents reporting using at least one technology solution to manage their equipment.

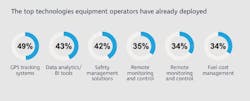

Teletrac Navman found that companies were working to address these issues by adding even more technology to their operations, particularly GPS tracking systems (49%) and data analytics/BI tools (43%).

The company also found that 88% of companies planned to invest in technology to help them manage maintenance expenses (45%), scheduling (44%), and utilization (43%) over the next 12 months. And looking even further ahead, about two in five planned to invest in data analytics/business intelligence tools as well as GPS asset tracking over the next five years. Comparatively, a little less than 1/3 of respondents planned to invest in predictive maintenance systems in the next five years.

All the same, regardless of which type of solution fleets invested in, "By integrating these tools into daily operations, operators are seeing measurable gains," the company concluded.

About the Author

Alex Keenan

Alex Keenan is an Associate Editor for Fleet Maintenance magazine. She has written on a variety of topics for the past several years and recently joined the transportation industry, reviewing content covering technician challenges and breaking industry news. She holds a bachelor's degree in English from Colorado State University in Fort Collins, Colorado.