Get out the scissors and cut the maintenance budget again. On second thought, use a chain saw.

Organizations squeeze the maintenance budget because it is not obvious that more money results in better outcomes. It is not obvious because of time.

Added money for a preventive maintenance (PM) system might not show results for a year or more. By the same token, the consequences of reduced PM might also not show up for a year or more.

This time delay is a trap has caught some smart people and has profoundly affected maintenance.

Human Development

Before we dissect the matter, let’s have a look at human development.

Do you remember the toughest lesson you had to learn as a teenager? It was: actions have consequences.

It is not that all causes lead to effects. It is subtler then that.

A young person might drive fast 100 times with no problem. But eventually – not always, but usually, they have to contend with the consequences of their actions – in this case speeding. The fact that they drove fast a 100 times with no bad outcome clouds the picture for them.

Young people are smart. If you tell them that driving fast will get them into an accident and they drive fast and don’t get into an accident, what are they to think? They think that for some reason they have special skills or are not under the rules that everyone else is.

Tragically, some kids never learn that lesson.

No Immediate Consequences

Back to companies who keep cutting maintenance budgets.

Cutting the maintenance budget is an action with consequences. But like the kid speeding on a joy ride, the consequences of cutting maintenance budgets might not show up for some time.

What is a smart manager to think? Perhaps they think they have escaped the consequence or are in some way extraordinary. Or maybe, they are ignorant of the consequence in the first place.

This is the way the world works, has worked and probably will continue to work.

Approach Equals Results

The Bible tells us that we reap what we sow.

To paraphrase this: your outcome is consistent with your actions.

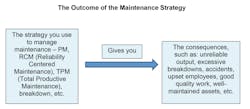

To rephrase this for the field of maintenance: The business strategy you use to care for your equipment gives you the consequences.

Therefore, when you are forced to rejigger old parts or scrounge junk yards for parts, you are choosing consequences. There is no morality, no good or bad here, just strategies and consequences.

The consequences are either consistent with, or inconsistent with, the goals of the company or department.

Strategies without Support

Different strategies require different supports and different logistics. For example, RCM requires time, facilitation, engineering knowledge and the power to spend some money to solve severe problems.

Plain vanilla PM needs some kind of scheduler, time to build or collect task lists, skilled labor to carry out the PMs, ability to follow up with corrective repairs, etc.

What happens when you chose a maintenance strategy and you don’t have the support in place? What do you call a politician who promises lower taxes without any idea how to deliver that, while keeping the level of services the same?

Strategies without support are illusions. They are smoke and mirrors. They are shams.

If you reduce support for maintenance – like cutting the training budget or reducing purchases of spare parts below the minimums, you force the department to change the strategy.

Your Decision

Organizations force the strategy by cutting resources and then complain about the consequences. That is like not studying for a chemistry test, failing it and complaining that the teacher did a bad job in some way.

You (collectively) picked the strategy and the strategy picks the consequences.

About the Author

Joel Levitt

President, Springfield Resources

Joel Levitt has trained more than 17,000 maintenance leaders from more than 3,000 organizations in 24 countries. He is the president of Springfield Resources, a management consulting firm that services a variety of clients on a wide range of maintenance issues www.maintenancetraining.com. He is also the designer of Laser-Focused Training, a flexible training program that provides specific targeted training on your schedule, online to one to 250 people in maintenance management, asset management and reliability.