Peterbilt upgrades Model 579EV and launches vocational 567EV

Through the decades, Peterbilt’s ardent customer base has always loved their older distinctive trucks like the Model 389 for its sweeping, low hoods and towering smokestacks, which its predecessor, the Model 589, retained when it first rolled off production lines last year (with, of course, plenty of technological updates added in). The Denton, Texas-based OEM had 5,000 orders as of last June, not bad for a truck that bucks the aero trend—smooth, sloped hoods—dominating the heavy-duty segment.

Peterbilt hopes the trucking industry will equally embrace its new trucks on the opposite side of the spectrum, the next generation Model 579EV and all-new Model 567EV. Both were unveiled at the 2025 ACT Expo in Anaheim this week.

Next-gen 579EV at a glance

The 579EV is a refresh from the original model for regional and drayage applications launched in late 2020. The new version offers three battery options, with a max 200-mile range, a 25% increase from the original. Using 350kW charging, the EV can reach an 80% charge in 90 minutes. Other enhancements include a new electronic parking brake (EPB) and standard Bendix Fusion Stop & Auto-Go Advanced. The company also said ergonomic, driver comfort, and the LED lighting were improved.

It also comes with cosmetic changes such as a distinctive grille with splayed grille bars and hood side panels that have bright bezels and blue accents.

567EV at a glance

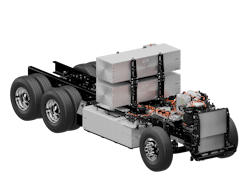

Peterbilt calls the 567EV “the industry’s first electric heavy-duty conventional vocational truck.” The work truck sector can spec the 567EV, which has a customizable frame layout and configurable PTO controls and switches, as a dump truck, utility truck, equipment hauler, and other applications.

The 567EV gets up to 250 miles per full charge. Customers can spec one of four different battery capacity options. Electric PTO options include a 25kW or 150kW rating.

Powertrain

Neither have an exhaust pipe to be seen, let alone protruding proudly above the cab. No, these battery-electric trucks get their power from the updated Paccar ePowertrain, a powerful motor that may not be visible, or even all that loud, but should garner the attention of fleets looking to reduce emissions but not at the cost of performance.

“The completely new ePowertrain is the heart of the new EV models and a culmination of five-plus years of arduous testing and developing a battery-electric platform befitting a Peterbilt,” Erik Johnson, the OEM’s assistant GM of sales and marketing, said during a media sneak peak in Denton earlier this month.

Highlights of the ePowertrain include:

- Midship-mounted eMotor: Dual electric motors and integrated 3-speed transmission offer seamless shifting without losing torque.

- Multiple power options can benefit different applications and needs, offering up to 605 hp and 1,850 lb.-ft. of torque.

- Lithium iron phosphate battery (LFP) chemistry

- Selectable three-stage regenerative braking

- Flexible architecture allows for integration with existing suspensions.

A big advantage is the ePowertrain’s ability to fit into a wide range of trucks customized to specific user needs.

“This new powertrain gives us flexibility of building different bodies, different customer expectations on the same platform,” Johnson said.

The other big thing is that “if you’re an operator, it operates like you’d expect a diesel to," explained Scott Newhouse, Peterbilt’s chief engineer.

About the Author

John Hitch

Editor-in-chief, Fleet Maintenance

John Hitch is the award-winning editor-in-chief of Fleet Maintenance, where his mission is to provide maintenance leaders and technicians with the the latest information on tools, strategies, and best practices to keep their fleets' commercial vehicles moving.

He is based out of Cleveland, Ohio, and has worked in the B2B journalism space for more than a decade. Hitch was previously senior editor for FleetOwner and before that was technology editor for IndustryWeek and and managing editor of New Equipment Digest.

Hitch graduated from Kent State University and was editor of the student magazine The Burr in 2009.

The former sonar technician served honorably aboard the fast-attack submarine USS Oklahoma City (SSN-723), where he participated in counter-drug ops, an under-ice expedition, and other missions he's not allowed to talk about for several more decades.