Cummins to invest $580M to prep engine plant for fuel-agnostic future

In preparation for a new line of sustainable, fuel-agnostic engines, Cummins is investing $580 million for new equipment and enhanced assembly lines at its Rocky Mount Engine Plant (RMEP) in Nash County, North Carolina. The project, part of Cummins' larger Destination Zero Strategy, will be supported by recently approved tax incentives and create about 80 new jobs. The plant has 2,000 employees currently.

“We are excited to be driving continued growth within Nash County and creating jobs that rely on high-caliber technology for the future,” said Steve Pinkston, Cummins RMEP manager, in a statement. “Cummins is focused on Destination Zero and getting there as quickly as possible. When we receive engagement from local partners like this, it helps us move faster toward a more sustainable future.”

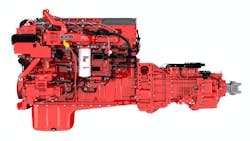

RMEP has produced over 5 million engines over 40 years, and the next generation will be efficient in terms of both production and operation. The fuel-agnostic platforms will be able to cater to a variety of customers who may choose advanced diesel, CNG, hydrogen, and even methanol (wood alcohol) or ammonia. Each version would start with a similar base engine and share parts commonality under the head gasket. Fuel-type dependent parts would be found above the head gasket. This strategy will be used for the B6.7 and the X15, and the new 10-liter portfolio called the X10. The X10, slated for 2026, will comply with Environmental Protection Agency’s 2027 regulations.

Read more: Cummins reveals X10 fuel-agnostic engine for 2026

“This investment is not just about engines; it's a testament to our unwavering commitment to the community and our vision for a sustainable and impactful future,” said Pinkston. “Our role extends beyond the production floor; it's about cultivating a thriving community where everyone can succeed. As we invest in innovation and growth, we're also investing in the community that has been our home for four decades and counting."

Last summer, Fleet Maintenance traveled to Cummins' Jamestown Engine Plant in New York. Click the video to take a look: