Q & A: ULSD Worries

Q: There was a lot of talk at the TMC Meeting about the quality of ultra-low sulfur diesel fuel. We haven’t had any quality problems so far with our fuel, but my drivers don’t entirely trust ULSD yet. How can we guard against getting a tank full of bad fuel?

A: The transition to ultra-low sulfur diesel (ULSD) fuel in North America—regardless of the type of vehicle it is going to be used in—and the changes in engine technology have created challenges for anyone who owns, runs or maintains diesel vehicle engines.

There are two culprits. First is the EPA-mandated reduction in sulfur levels, from 500 to 15 ppm, designed to protect emissions technology in newer equipment, which is sensitive to sulfur contamination. The objective is to reduce particulate matter (PM) and oxides of nitrogen (NOx) emissions.

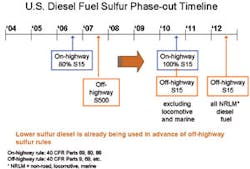

To accomplish that objective, all U.S. on-road diesel vehicles equipped with 2007 or newer certified engines are required to use ULSD, and refineries have been required to produce the fuel since June 1, 2006. Although some higher-sulfur (500 ppm) on-highway fuel is still available in places, the transition to ULSD is nearly complete.

Now the focus has switched to ULSD for off-highway vehicle use, which will be phased in over the next six years. Even though not required until 2010, the transition has begun, well in advance of it being required. That means that ULSD is appearing in off-road applications, something many users may not be aware of.

As ULSD becomes more prevalent in the U.S., you need to aware that there are six key ways lower sulfur content in fuel impacts engine operability and performance:

1. Reduces lubricity. Sulfur serves as a natural lubricant for fuel pumps and injectors. When sulfur is reduced, beware of system wear. Today, all ULSD is being treated with lubricity improver additives to meet the ASTM D 975 diesel fuel specification.

2. Lowers oxidative stability, ensuring that the fuel will be able to resist degradation under stress and exposure to air. New emissions-compliant engines stress the fuel more than previously used engine technologies.

3. Lowers conductivity. ASTM D 975 will include a conductivity specification in the near future.

4. Lowers solvency so it is less able to solubilize impurities and oxidative byproducts. This can increase injector deposits, reduce fuel economy and negatively impact performance.

5. Lowers density, resulting in slightly lower energy content, thus decreasing fuel economy.

6. Changes the cold flow behavior. The refining process that removes sulfur affects the fuel’s composition, making it slightly waxier. Below a certain temperature, crystallization, gelling and viscosity increase. The result is that vehicles may not operate as well in the cold weather.

The second culprit to be aware of is engine technology changes. Not only do today’s engines use advanced emissions control systems, but they also operate under tougher pressure and temperature conditions. In addition, manufacturing tolerances are very tight, making them susceptible to wear and deposits.

But when you put these two culprits—lower sulfur and new engine technology—together, you get a double whammy. High fuel quality is essential. But how do you assure yourself that the fuel you use is high quality?

There are a number of ways you can get this assurance by working with your fuel supplier. First, know what fuel you are buying, know its sulfur level as well as whether or not it contains biodiesel—and if so, how much. Then, make sure your fuel meets an appropriate specification. ASTM D 975 is the accepted minimum fuel quality standard. In addition, TMC (Technology & Maintenance Council) has a fuel quality recommended practice. Many engine manufacturers provide fuel guidelines as well.

Another way is to be aware that in northern climates, diesel fuel composition should change in the winter months to ensure low-temperature flow. This will provide assurance that your equipment will start and run effectively.

You also should consider using fuel additives as part of your regular preventive maintenance program. For example, a fully formulated multifunctional detergent designed for ULSD can keep your equipment in shape in seven ways:

1. Cleans up the fuel system and keeps it clean.

2. Protects fuel pumps from wear.

3. Prevents corrosion.

4. Fights acid wear from EGR gases.

5. Removes or displaces water.

6. Reduces filter plugging.

7. Keeps pistons cleaner.

In cold weather, the addition of a cold flow additive can keep crystallization, gelling and viscosity increase at bay.

This will save you money by extending the life of your equipment, reducing downtime, improving TBN retention, which extends lubricant life, improving the length of time fuel is stable during storage and restoring and maintaining engine fuel economy.