Mike Rowe on diesel tech shortage: ‘The math ain’t good’

While kicking off the annual Virtual Diesel Expo, organized by Diesel Laptops and Alliant Power, Diesel Laptops founder and CEO Tyler Robertson estimated that there are 80,000 open jobs for diesel technicians in the U.S., while community colleges add about 10,000 new technicians to the trade each year.

“Huge differential there, and it's getting worse every year,” he assessed to the virtual attendees.

According to the U.S. Bureau of Labor Statistics, from 2020 to 2030, the industry will add 28,100 openings for diesel service technicians and mechanics each year. Clearly, the technician shortage is and will continue to be a major issue for commercial vehicle fleets and shops. That's why Robertson and Alliant Power President and CEO Houman “HK” Kashanipour turned to Mike Rowe, arguably the most ardent and well-known advocate for skilled labor in the U.S., to put the problem into context and how stakeholders can help reduce that “huge differential.”

Rowe, the host of "Dirty Jobs," which is back in production, and several other programs that highlight the benefits of hard work and skilled labor, started off by addressing the industry’s dire math problem.

“Sometimes things have to go splat before they get better,” Rowe offered. “I don't know what splat really looks like in this case, but I do know that the math ain’t good.”

Rowe cited the 11.5 million open jobs overall in the U.S. Along with the deficit of diesel techs, the country also needs new truck drivers, welders, plumbers, electricians, and several other skilled trades workers. The big issue is that four out of five of these [11.5 million] open jobs do not require a college degree, yet the educational system is still promoting four-year colleges and universities as the surest pathway to success.

“You’ve got $1.7 trillion in student loans on the books, and parents and guidance counselors are still telling a whole generation of kids that they're going to be screwed if they don't get a four-year degree,” Rowe surmised. “We’re lending money we don't have to kids who are never going to be able to pay it back to train them for jobs that don't exist anymore. Meanwhile, in your industry, 80,000 positions are sitting there wide open.”

The open jobs will continue to increase as the silver tsunami, the name for the massive wave of retiring boomers, edges closer to making landfall.

“What worries me the most is the simple fact that most of the people in that industry right now are over 55,” he said. “And they're retiring faster than ever, and there's nobody in the pipeline. If there were an alarm to ring, a bell to clang, this would be the time to do it.”

As an example of what is at stake, he mentioned the workers who crawl into a cement mixer with 90-lb. jackhammers to chip away all the hardened material.

“It's a powerful thing to ponder when you think about those guys not showing up for work one night and suddenly, all the concrete trucks in the country don't have any room in the drums,” he said. “Every construction project stops, road construction stops, office construction. All of it stops.”

Read more: Three ways to train and retain quality entry-level technicians

The dirty job stigma

Rowe noted he is not against higher education, but promoting a bachelor’s degree should not come by way of devaluing the vocational trades.

“People think I'm somehow anti-education because I talk negatively about the cost of college. I'm not,” Rowe explained. “To be as clear as possible, you are screwed without an education. But the idea that the best education for the most people is a four-year degree—that ship has sailed. It's just not true."

He is, however, against high schools’ “boneheaded, inexplicable decision” several decades ago to eliminate trade-focused curriculum.

“In 1978, when I was in high school, we had a wood shop, we had a metal shop, we had auto shop, and we had welding clinics. We had all this stuff,” Rowe recalled. “By the time I finished [high school], it was all gone.”

The stigmatizing of the trades during that time stuck with Rowe.

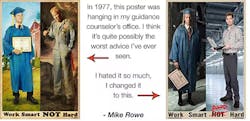

A poster in his guidance counselor’s office juxtaposed a smug diploma-holding young man in mortar and robes on a bright university campus against a slouching, soot-covered Neanderthal holding a monkey wrench like a club. The poster read “Work Smart NOT Hard.”

Since then, he has made a career of destigmatizing messages like this as an author of books such as "Profoundly Disconnected" and hosting “Dirty Jobs.” Rowe also founded the MikeRoweWORKS Foundation in 2008, which has awarded $5.2 million in “Work Ethic” scholarships to more than 1,200 students.

“They've got to write an essay and make a video, provide references—make a persuasive case for themselves,” Rowe explained. “I don't care about grade point average, but I care about attendance.”

Applicants must also sign a S.W.E.A.T (Skill and Work Ethic Aren't Taboo) Pledge, where they must affirm they will adhere to 12 basic beliefs that Rowe himself values and said helped him achieve success.

“It speaks to things like gratitude and delayed gratification, and a decent attitude,” he said, as well as soft skills including “tuck your shirt, try not to be a schmuck, and be respectful.”

Rowe made his own poster. He posed as a downtrodden graduate, side-by-die with a cable technician holding a ruggedized computer. That one reads “Work Smart AND Hard.”

The messaging problem

That reimagined poster perfectly sums up the modern diesel technician. Sure, they will still lug around a giant wrench on occasion, but troubleshooting more often than not starts with plugging a diagnostics device into a truck port to analyze the data. Maintenance facilities are now treated more like high-tech truck hospitals, where the best and brightest workers assess issues in a triage bay. As electric vehicles rise to prominence, these workers are also expected to learn complex electrical skills. These jobs pay well and offer new challenges every day.

But companies looking to fill these roles “aren't quite sure how to articulate the existence of opportunity,” Rowe said. “So they wind up apologizing and saying, ‘Hey, these jobs are better than you think.’”

He thinks companies looking to hire diesel techs, or any skilled trade, could take a page from the recruiting strategy of the U.S. Marine Corps.

“The Marines say, ‘We're not looking for everybody; we're looking for a few—a few who are willing to get up early, stay late, do the hard thing,’” Rowe said.

Those are the characteristics Rowe looks for in scholarship recipients, and for fleets dependent on working trucks to do things like delivering goods, picking up garbage, or pouring cement, sometimes they require long hours and difficult work. To help prevent a new hire from being an ex-employee, not making the messy side of the job a dirty secret and being transparent is the wise choice.

Attendees of the Virtual Diesel Expo were able to ask Rowe questions, and one asked how employers can improve their messaging to diesel technicians.

“How do you get around the stigmas, the stereotypes, and the myths and misperceptions that keep kids from exploring a career in the trades?” Rowe asked, before answering, “The only way to do that is to introduce them to somebody who looks like them, somebody who they can relate to.”

This isn’t about physical attributes but rather someone working at the shop around the same age “who went to diesel mechanic school and who's now making a comfortable living, paying his or her bills, living mostly debt free—somebody who has balance in their life."

“You have to hear from people who have prospered as a direct result of mastering that skill, and then going to work,” Rowe asserted. “The only things I've ever seen that are truly persuasive are honest conversations with people who have taken the path. There's just no substitute for it.”

Recruiting women

Diesel Laptops’ Robertson also mentioned that 96% of diesel technicians are male. That’s also a math problem, as more than half the population is female yet are not widely available to help fill those 80,000 jobs. “We're going to have a hard time filling all these jobs if it's all guys working,” Robertson said.

Read more: How to build a more welcoming atmosphere for trucking employees

The root cause of the disparity stems from the trade’s image problem, Rowe believes.

“The myths and the misperceptions that keep a lot of guys from exploring new trades are exponential when it comes to women,” he said.

This is one myth Rowe was eager to bust. He mentioned a woman named Chloe Hudson, who earned a Work Ethic scholarship.

“Chloe was this beautiful woman who applied for a welding scholarship four years ago, and her application was great. Chloe knocked it out of the park,” he recalled. “But what I loved about her was she said she was this close to borrowing something like $400,000 to go to medical school. Her dream was to become a plastic surgeon, but she just balked at the money at the last moment and said, ‘I'd rather do something I can afford to do.’”

Rowe noted she now makes $180,000 a year welding at a manufacturing plant. She is only one of three female welders at that plant, but Rowe said “she is their rockstar.”

He explained that many more companies are looking to hire women, and his foundation has responded by “mak[ing] a concerted effort to reach out to women.”

“That is a huge opportunity for [the trucking maintenance sector], in my view,” Rowe said. “If you can reach out to women and show them what's actually available, I think you'll be surprised at what comes back.”

To register for the Virtual Diesel Expo to listen to Rowe's full talk and several other discussions relevant to diesel engine maintenance, visit HERE.

About the Author

John Hitch

Editor-in-chief, Fleet Maintenance

John Hitch is the award-winning editor-in-chief of Fleet Maintenance, where his mission is to provide maintenance leaders and technicians with the the latest information on tools, strategies, and best practices to keep their fleets' commercial vehicles moving.

He is based out of Cleveland, Ohio, and has worked in the B2B journalism space for more than a decade. Hitch was previously senior editor for FleetOwner and before that was technology editor for IndustryWeek and and managing editor of New Equipment Digest.

Hitch graduated from Kent State University and was editor of the student magazine The Burr in 2009.

The former sonar technician served honorably aboard the fast-attack submarine USS Oklahoma City (SSN-723), where he participated in counter-drug ops, an under-ice expedition, and other missions he's not allowed to talk about for several more decades.