Focus on coolant filtration; your engine will thank you

Key takeaways:

- Coolant filtration removes harmful contaminants that can reduce its coolant's ability to remove heat, decreasing component wear and tear

- But finding the right coolant filter for a particular truck means considering several factors, from the volume of the cooling system to the thread size of the filter

- Also, keep in mind what types of filters are designed for certain applications, and the environmental factors that may impact your filter

Coolant filtration systems used to be standard equipment in diesel engine builds. In recent years, however, some manufacturers have started offering them only as options (at additional cost) or removing them altogether.

As noted in SAE Technical Paper 881270, approximately 40% of problems in heavy-duty diesel engines are related to cooling systems. However, most of these issues can be prevented with the use of quality coolant, proper system maintenance, and filtration.

Evolving global diesel emissions standards have forced major changes to cooling system temperatures, operating conditions, chemistry, and flow rates. All these factors are driving the need for more efficient coolant filtration at a time when the trend is to remove the systems that have traditionally provided it.

In addition, coolant for heavy-duty diesel engines is now available in more varieties than ever, and original equipment manufacturer (OEM) recommendations often differ. A bewildering array of choices—including water-based, glycol-based, additive chemistries, supplemental coolant additives (SCAs), and service/maintenance intervals—have caused general confusion industry-wide. Many end users are unaware of the benefits coolant filtration provides, why it’s essential to reliable equipment operation, and what they risk losing without it.

Why coolant filtration matters

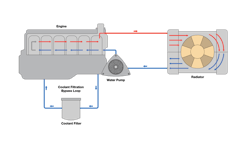

Proper coolant filtration reduces unnecessary downtime by filtering harmful contaminants from the coolant that can interfere with heat removal and contribute to component wear and failure. Significant benefits to the cooling system include:

- Extended water pump life

- Maximized corrosion protection

- Longer coolant life

- Improved heat transfer

- Increased thermostat and radiator durability

- Lower cooling system maintenance costs

In contrast, poor coolant filtration can cause:

- Worn piston rings

- Scuffed piston skirts

- Premature fouling or failures of water pumps, thermostats, and radiators

Threats from within

Contamination doesn’t just come from outside the cooling system. Internal chemical reactions can create substances that clog filters and restrict coolant flow, potentially causing overheating and component damage.

Additive dropout is when one or more of the chemicals in coolant—known as additives—solidify and drop out of solution. Additives are used to protect the cooling system and engine from corrosion, scale, deposits, and other issues. Additive dropout can occur if the system isn’t properly maintained or incompatible types of coolant are mixed together.

Silicate gelling is a type of additive dropout that can occur in coolants that use silicate-based formulations to inhibit corrosion. Silicate additives precipitate out of the coolant, forming a gel-like substance. Low pH, excessive silicate levels, extreme temperatures, and poor water quality are among the most common causes.

Sources of contamination

Contamination in the cooling system is more common than many people realize. In fact, some particulate matter (PM) may already be in the system as soon as it leaves the factory. This challenge is a common by-product of the casting process. Engines have complex internal shapes that are often made via a casting process. Manufacturers mix high-purity sand with resins, oils, or clay to create core sand, a compound that can stand up to the heat of molten metal but is flushed out once casting is complete. Unfortunately, traces of it are often left behind in the system.

Contaminants such as metal shavings, additive dropout, and other solids are also created under normal operation. In addition, the use of impure water or dirty containers during service and maintenance tasks can introduce dirt and silt into the cooling system.

Poor-quality coolant, spent or degraded additives, or overtreatment with SCAs will result in the formation of insoluble substances, such as silicate gelling, within the cooling system. If concentrated coolant is mixed with hard water, scale can form on hot surfaces such as cylinder liners, cylinder heads, and water pump seal faces.

Types of heavy-duty coolant filters

The ideal coolant filter is determined by the needs of the equipment and its operator. These may include:

- The volume of the cooling system

- Filter and coolant service intervals

- Coolant technology

- SCA requirements

- Filter height

- Thread size

- Environmental factors

Some coolants can use chemical coolant filters for additive replenishment throughout their service interval. No SCAs are required for organic acid technology (OAT) products and related formulations like nitrited organic acid technology (NOAT), which can use non-chemical “blank” coolant filters.

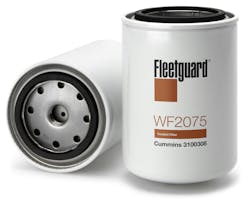

Standard coolant filters typically require service intervals of less than 500 hours or 25,000 miles (40,000 km). These filters use a cellulose medium to capture debris and contaminants. Immediate-release technology is used to ensure the right amount of SCA is available throughout the service interval.

Extended service interval coolant filters are designed to last up to a year—approximately 4,000 hours of operation or 150,000 miles (250,000 km). Some advanced extended service coolant filters use synthetic media and a coated tablet technology to release the proper amount of SCA throughout the service interval.

What if there's no place to attach the filter?

Some OEMs that no longer offer standard coolant filtration still provide ports for add-on or aftermarket systems. If your equipment doesn’t have a coolant filter head, there are aftermarket options available that will allow you to add one. Many engines have ports or hose fittings that enable a competent diesel mechanic to tap into the cooling system. Failing that, there are products that will allow you to splice an appropriate fitting into the system. This is a more invasive process requiring more time, equipment, and know-how.

The physical package size of the coolant filter and the location of the filter head will be key factors when determining specifically where the filter can be mounted. There are several common industry-accepted thread sizes, plus a variety of filter heights to accommodate most applications. It’s also important to ensure there’s enough clearance for filter removal and service.

Your application and environment will help determine the type of filter you need:

- Standard head filters are intended for on-highway use with regular filter services.

- Severe-duty head filters are designed for off-highway applications where the environment can be severe, such as construction or mining.

- Dual-head filters can handle the large system volumes required by generator sets and other high-horsepower applications.

Physical and environmental factors to consider when selecting coolant filters include:

- Maximum and minimum system and ambient temperatures

- Vibration

- Hose routing and specifications

- Filter head pressures and restrictions

- System fittings and shut-off valves

As performance demands continue to increase, the need has never been greater for coolant filtration—as part of a broader filtration science approach—to remain as a critical engine component and a key part of a complete preventative maintenance regimen.

Although engines sold without coolant filtration may offer lower up-front costs, end users risk paying more over time without the essential protection these systems provide. They remain indispensable, even if no longer provided as a standard feature.

About the Author

William Huff

Senior materials science engineering chemist

William Huff is a senior materials science engineering chemist at Atmus Filtration Technologies. In his role, he works to support Fleetguard coolants, coolant filters and related products. This includes new product validation and development, working with customers to solve coolant-related issues, and conducting training sessions and webinars on coolants for customers. William has worked for Atmus for eight years, with five years of experience in the company’s coolant analysis lab. He earned a bachelor’s degree in analytical chemistry from Tennessee Technological University.